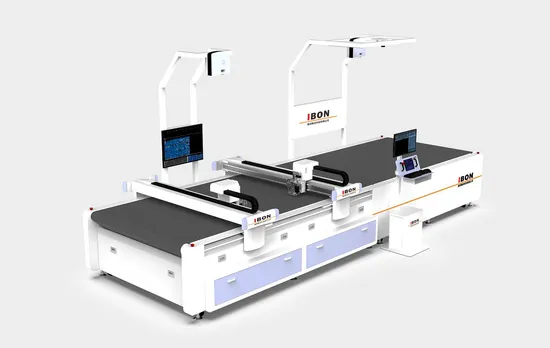

Genuine Leather Digital Automatic Oscillating Knife Cutting Machine for Shoes and Bags \Belts Cutter

Basic Info.

Model NO.

IB-1660

Certification

CE

Condition

New

Control

Automatic

Application

Paper, Plastic, Leather, Fabric, Rubber

Power Source

Electric

Layout

Horizontal

Product Name

Leather Cutting Machine

Working Area

2150*7000mm

Applicable Material

EVA, Sponge,Rubber, PVC

Positioning Accuracy

±0.01mm

Supported Files

Plt, Dxf

Transmission System

Servo Motor, Rack, Belt

Fix Way

Vacuum Absorb

Motor

Japan Mitsubishi

Power

220V-380V, 50Hz

Transport Package

Wooden Cases

Specification

1600mm*6000mm

Trademark

IBON

Origin

China

HS Code

844110000

Production Capacity

3000 Set/Year

Product Description

Product Description Genuine Leather Digital Automatic Oscillating Knife Cutting Machine for Shoes and Bags \Belts cutterHere is the workflow of the intelligent leather cutting machine:

Defect Marking and Detection: Mark defects on the leather surface with a pen. The machine uses its camera function to automatically detect the marked defects and the material's edges. It can also identify unmarked but obvious defects. Layout and Path Transmission: Import the layout, select the required cutting patterns, and send the cutting path to the machine. Precision Cutting: Press the start button, and the machine precisely cuts along the planned path, avoiding defective areas and ensuring flawless cut pieces.

Product Parameters

| Workingsize: | 2150mm*7000mm |

| Product name: | Car leather covers and floor mats cutting |

| Machine size: | 1600mm*6000mm |

| Feedingmethod: | automatic feeding material |

| Airpressure: | 0.75-0.85Mpa |

| Cuttingaccuracy: | ±0.1mm |

| Cuttingthickness: | 0.1-30mm (depending on the material) |

| Transmissionmotor: | Japan Mitsubishi |

| Transmissionmode: | Linear rail and rack |

| Dataformat: | PLT,DXF |

| Transmission interface: | Ethernet ,USB |

| Fixedmode: | Vacuum absorb |

| Ratedvoltage: | AC220V-380V,50HZ |

| Ratedpower: | about 10KW |

Certifications

With high-precision CCD positioning function, the cutting is more accurate

Automatic pulling and unloading, saving time and effort

Select Taiwan linear guide drive system, accuracy ±0.1mm

Improves cutting efficiency and helps customers maintain a high cutting rate competition level

The combination of software and digital cutting machine provides an intelligent cutting platform to form a perfect advertising production system

After Sales Service

Company Profile

>> 1600mm Swing Diameter Turning Cw61160b Horizontal Heavy Duty Lathe Machine

>> Hot Selling Carbon Steel Sheet SPCC-SD/DC01/DC04/ 0.1-3.0mm / Width 300-1600mm ASTM Cold Rolled Steel Sheet

>> Plastic Express Bag Polyethylenen Air Bubble Film Making Machinery

>> Hot Sale Inclined Guide Rail Electric Bench Hobby Lathe Machine

>> Kinger New Design Heavy Load Automatic Unloading Mixer Bucket Home Use Construction Use Excavator Loader Attach

>> Light Drop Weight Tester for soil bearing capacity

>> Viton Rubber Heat Shrinkable Tube

>> Horizontal Chemical Plough Mixer Plough Mixer with Workbenches

>> High Speed Bluetooth 80mm Thermal Receipt Printer with Autocutter

>> Cosmetic Airless Spray Bottle 15ml 30ml 50ml 80ml 100ml Transparent Airless Pump Bottle

>> Ultralight Packable Machine Washable 3-4 Persons Camping Mat

>> Sausage Filler/Sausage Stuffer/ Meat Processing Machinery/Sausage Making Machine/Sausage Filler Stuffer

>> Airline Disposable Slippers Non-Slip Terry Cloth Airline Slippers Aero Soft Slippers

>> FUJI Factory Manufacturer Panoramic Lift Glass Elevator with Sightseeing Elevator Home Elevator Villa Passenger Lift Passenger Elevator Lift China Lift

>> CT3510 Small Turning Lathe Machine for Metal with Factory Price

>> HY-1730B Post bed sofa and car seat compound feed heavy duty industrial sewing machine

>> Automatic Feeding Material Tube Bending Machine/ Automatic Tube Bender/ CNC Tube Bender/ CNC Tube Bending Machine

>> Carbonylation in High Pressure Reactors

>> 0.45um Absolute Pes Membrane Pleated Filter Cartridge for Sterile Filtration

>> High Performance Multi Groove Knife Blocks for Winders

>> Stainless Steel 304 Perforated Metal Mesh Sheet

>> Floating fish feed extruder machine floating fish feed pellet machine for fish farm

>> High Quality Racing Car Metal Model Vehicles

>> 12KG Manufactory Wholesale Energy Saving Twin Tub Semi Automatic Washing Machine

>> Hydraulic pump Log Splitter Pump for wooden machine CBNA-6.6/3.6

>> Wholesale Factory Fresh White Peeled Onion in Mesh Bag Carton

>> Welding Machine for HDPE Tank Acid 90 Angle Welding China Factory

>> Haijia Quality High Speed Water Jet Weaving/Textile Power Loom with Electronic Control Crank/Cam/Dobby Shedding

>> Wholesale CE Approved Adult Battery Operated One Seat 24V/500W Four Wheel Drive Smart Electric Heavy Duty Mobility Scooter with Handicapped

>> Hanmix Passenger Car Tyre Gcc Saso ECE Top Quality R14 R15 R16 Commercial Light Truck LTR Heavy Duty Radial Truck Tire China Factory Wholesale New Tyre Llanta