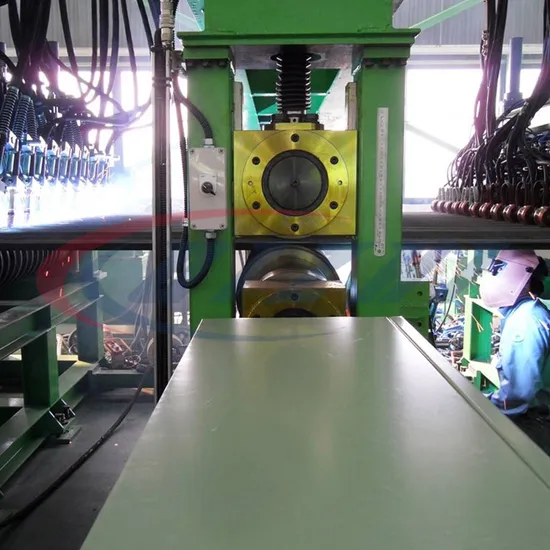

Automatic Membrane Panel Production Line (GMAW)

| US$150,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

AMPWL(GMAW)

Style

Vertical

Frequency Range

50/60Hz

Type

Continuous Seam Welder

Welding Method

Gmaw

Optional Welding Method

Saw

Torch Qty

6 or Higher

Automation

High Automation

Transport Package

Nacked Packing in Container

Specification

32-76mm

Trademark

QIZHI

Origin

China

HS Code

85153199

Production Capacity

50sets/Year

Product Description

Automatic membrane panel production line (GMAW) Product Description QIZHI provides customized membrane panel welding production line for boiler manufacturers. We can provide SAW method or MIG method production lines. The complete line consists of several machines, such as main machine, uncoiler, finishing machine, automatic feeding in/out device, storage rack, pipe polishing machine, membrane panel bending machine, etc.Features provide streamlined logistic for tubes and flat steels; specialized conductive mechanism (international famous brand) to direct current to each welding seam and improve anti-interface ability; improve the clamping force of the upper pressing roller to effectively ensure the clamping and closing force of the groove wheel on the panel during welding, as well as the stability of the center position of the flat steel; more welding torches can be applied in the whole production line. Specifications

| Tube size: | 32-76mm |

| Tube thickness: | 3~9mm |

| Flat steel width: | 10~110mm(±0.1mm) |

| Flat steel thickness: | 4~10mm ±0.1mm |

| Max. panel width: | 1600mm |

| Max. panel size: | 12000*1600mm |

| Welding speed: | 500-800mm/min |

| Welding method: | Pulse MIG |

Our machines have been widely recgonized by users such as..but not limited to:

1. Dongfang Boiler(DEC)

2. Hangzhou Boiler Group (HBC)

3. Taiyuan Boiler Group Co., Ltd.

4. Harbin Boiler Company Ltd.

5. Shanguo Boiler Group

6. Jinan boiler Group Co., Ltd.

We sincerely welcome you visit our workshop in your convenient time.

>> Hose Bottom Loading Arm with API Dry Break Coupler

>> Custom OEM New Design Men Tank Top Plain Color Men Tank Top Wholesale Price Men Tank Top Manufacturer

>> Fast Speed Electric Motorcycle with Powerful Motor

>> Rechargeable Soft Multifunctional LED Camping Lantern Light for Outdoor Camping

>> Shredder Tire Tread Cutting Recycling Machine Waste Tire Tread Cutting Processing Machinery

>> Double glass thermal break low u value sliding sash windows for villa

>> Waterproof WBP glue new zealand radiata pine LVL for house framing timber

>> Chlorinated Polyethylene CPE 135A Is Used in The Plastics and Rubber Industries

>> Stage Atomasphere Equipment Single Red 200MW*8PCS Moving Head Laser Light

>> PE600X900 Jaw Crusher for 120t/Hr Gravel Stone Production Line

>> Modern Luxury Design King-Size Bed Frame Upholstered Tufted Fabric Headboard Dark Grey Noiseless and Easy to Assemble

>> Industrial Ultrasonic Vibrating Rod Reactor Separation Emulsification Homogenization Refining

>> Animal Design Mesh Bath Sponge

>> Wholesale Leek Slices with Good Quality (10 mm)

>> Durable Cake Dough Making Machine Spiral Mixer Removable Bowl Dough Mixing Machine

>> Water treatment filter media with sponge cotton aquaculture PP plastic white black biological ball

>> Laser Welding Machine Aluminum Plate Welding

>> NAVIFORCE NF9155 Men's Watch Stainless Steel Mesh Japan Movt Quartz Watch Luminous Hand Watch

>> MAICTOP car lighting high quality head lamp for Camry 2018 headlight USA Other Headlights

>> Mindary original refurbished machine blood analyzer machine Mindary BS-400 fully automatic chemistry analyzer

>> Automatic Potato Carrot Fruit Washing Machine Vegetable Bubble Washer

>> BSCI and Sedex 4p Certificated Factory Directly Sell Hotel Face Towel with Customized Logo

>> 2025 HS-Laser 2000W Handheld Refrigerant Fiber Laser Welding Machine for Metal Welding

>> 2024 New Oulifu Embroidery Machine Cap Embroidery Single Head Ol-1502c

>> Plastic Recycle Machine PP PE Bottle/Container/Profile Granulation Equipment New Hard Material Granulator Plastic Recycling Machine

>> Long Service Life Modern Outdoor Waterproof for LED Garden Light

>> 2021 Cyclist Polarized Bicycle Eyewear Road Bike MTB Outdoor Sport Sunglasses Protection Glasses Windproof Gafas

>> Anti Caking Agent Paste for NPK Fertilizer High Quality From Plant

>> Excavator Electromagnet for Lifting Steel Scrap

>> 2-19mm CE SGCC Accredited Flat /Bent /Hardened Glass/Tempered Glass/Safety Glass/Toughened Glass