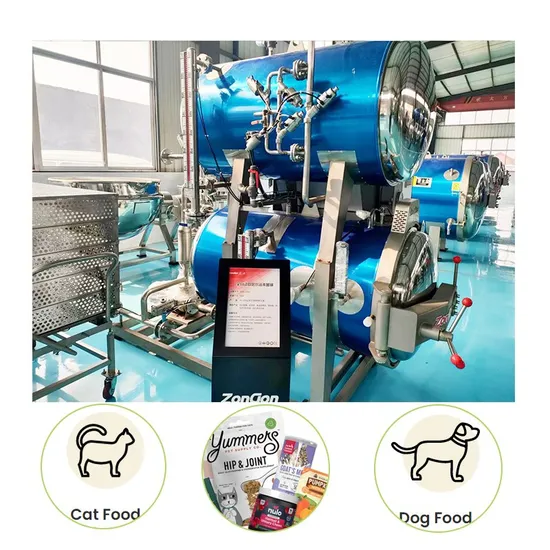

Wet Pet Food Retort Autoclave High Temperature Sterilization for Cat Dog Food

| US$15,500.00-61,000.00 | 1 set (MOQ) |

Basic Info.

Model NO.

ZG-SC

Customized

Customized

Certification

CE, Mom, Dosh, Saber, ASME

Automation

Automatic

Principle

Static

Energy

Heat Sterilization

Property

Physical Sterilization

Type

Retort Sterilizer

Delivery

60days After Deposit

Medium

Water, Steam, Air

Material

SUS304

Auxiliary

Steam Boiler, Air Compressor, Air Tank, Water Tank

Item

Autoclave/Sterilizing/Sterilization

Transport Package

Depends on Models

Specification

depends on models

Trademark

ZonGon

Origin

Zhucheng, China

HS Code

8419810000

Production Capacity

200sets/Year

Packaging & Delivery

Package Size

350.00cm * 220.00cm * 240.00cm

Package Gross Weight

1200.000kg

Product Description

Product Description

For customers with large packaging products and high production capacity requirements,you need a water immersion sterilization retort.Because it can help you achieve better sterilization effects and achieve greater yields.

Double layer tanks water-immersion autoclave

1. Save energy. The hot water used in the sterilization process can be recycled, which can effectively save energy and reduce production costs.

2. Shorten the sterilization time. The double-tank hot water cycle is used for sterilization, and the water in the hot water tank is heated to the temperature required for sterilization in advance, thereby shortening the sterilization time and improving the work efficiency.

3. The sterilization pot adopts hot water circulation and immersion sterilization methods. During the sterilization process, the circulating water in the sterilization tank is constantly switched up and down, which ensures the heat distribution at any point in the sterilization tank from heating, heat preservation to cooling. Uniformity, effectively eliminating the dead angle phenomenon in the sterilization process, making the shelf life of the product more stable and long.

4. The temperature in the sterilization tank is always stable in all stages of the sterilization process, which ensures the qualified rate of the F value.

5. Fully automatic control system. The entire sterilization process is controlled by computer PLC, which can be completed at one time without manual operation. Using a graphic tablet, using the screen for touch control.Pressure and temperature are displayed digitally, and various pressure and temperature modes suitable for any product can be pre-programmed into the computer.

6. The function of measuring F value. Each autoclave can be equipped with an F-value measuring instrument. The measuring instrument has the function of measuring the value. The F-value software calculates the F-value every 3 seconds(based on your own need). All sterilization data, including sterilization conditions, F value, time-temperature curve, time-pressure curve, etc., can be saved or printed after being processed by the data processing software to facilitate production management.

7. The simulated temperature control system can set up a multi-stage heating mechanism. According to the requirements of different foods for sterilization conditions, different heating and cooling programs can be set at any time. The multi-stage heating sterilization method can be used to limit the heat that the food can withstand. To the smallest, the color, aroma and taste can be perfectly preserved, so that each food can be conditioned and sterilized in the best state. The sterilization temperature is accurate to ±0.5ºC, which can avoid the phenomenon of over-cooking or incomplete sterilization of products.

8. 100 sterilization formulas can be stored in the PLC for selection and use.

Retort machines made by ZonGon machinery used full sus 304 material,more stable construction.Fully automatic controlled,liberate the hands of staff.Big size SIEMENS control panel,more clearly showing on what is the process going.Fault alarms are accompanied by indicator lights, allowing the entire sterilization process to be completely under the control of the operator.The emergency stop button helps you quickly and safely stop all work processes.

Based on your different packages,we would suggest different loading parts:1.trays,pallets and trolleys;2.baskets,trolleys,and heat resistant pp spacer.

Scope of application

What is your processing food product?What is the package type?

In fact,our high temperature sterilization machine suit for most kinds of packages products.Waterproof and heatproof packages.Low acid products.After sterilization, the product can achieve commercial sterility.

Product Parameters

Autoclaves belongs to customization style equipment,widely used in food processing field,new technology development labrotary,machine rents company......We supports various models and functions machines' customization service.Following show 5 of our standard models information for reference.

| Model | Diameter(mm) | Tube length(mm) | Basket | Max working Pressure(Mpa) | Max working Temperature(ºC) |

| PL-06-06 | 600 | 600 | 1 | 0.3 | 130 |

| PL-07-12 | 700 | 1200 | 1 | ||

| PL-09-18 | 900 | 1800 | 2 | ||

| PL-10-22 | 1000 | 2200 | 2 | ||

| PL-12-30 | 1200 | 3000 | 3 | ||

| PL-12-36 | 1200 | 3600 | 4 | ||

| PL-14-40 | 1400 | 4000 | 4 | ||

| PL-15-63 | 1500 | 6300 | 6 |

Certifications

Autoclaves is a kind of pressure vessels,it belongs to special equipment, and formal production and manufacturing can ensure the personal safety of users from the source. Various countries have strict requirements for the production and manufacturing of pressure vessels.ZonGon machinery is a formal manufacturer of pressure vessels in China.Each set of our retort's production meets specifical equipment manufacturing requests.

Company Profile

Our factory located in zhucheng city,shandong province,China.It is a city of food processing machinery.We establised in year 2002.For so long time,our factory engaged in retort machines production and technology development.Our customers all over the world.And we hope more and more food processors can use retort machine made by ZonGon machinery.

Customers cases display

Followings show you some of our customers cases

After Sales Service

Our service not only before order consulting,but also after sales installation guidance and debugging,operators training issues arrangement.And other after sales services.

FAQ

When you spend a huge amount of money buying a device from the internet,and the seller is located tens of thousands of kilometers.I can totally understand that you will feel very insecure.You will have many questions and situations want to confirm again and again.First,i list some simple but important questions and answers.More questions can be talked later on our directly communication.

Q1.Are you original manufacturer of horizontal type retort/autoclave/sterilizer machines?

A:Yes, we are zhucheng zhonggong machinery co.,ltd located in the food machinery city:zhucheng,China.We

establised in year 2002,and our main products are retort machine,automatic retort food loading&unloading system.

We are formal pressure vessel manufacturer that have our own production license of special equipment

People's Republic of China.We can guantee that each of the pressure vessel is both under supervising of our govenment and

our own quality inspectors before delviery.

Q2:If i buy your autoclave machine,how could i install,debug and use it?

A:After you have purchased our equipment and the machine arrive at your factory, you can make an appointment

with our engineers to provide on-site guidance on installation, debugging, and training. The specific operation is set according to your needs.

Q3:What is your warranty policy?

A:Our entire machine is guaranteed for one year (excluding vulnerable parts), and during the warranty period,

any component damage caused by quality reasons all could be in free shipping of new parts.Damaged parts that

exceed the warranty period require pay the part's price and shipping fee for purchase. Many of the accessories

we use are internationally renowned brands. If you don't want to purchase from us, you can purchase them locally

based on the accessory nameplate.

>> Commercial Heavy Duty Cardio Gym Equipment Motorized Electric Treadmill

>> Jewellery Fiber Laser Engraving Marking Machine

>> Hight Quality 1.5m Buddy Inflatable Soccer Zorb Ball Bumper Ball for Rental

>> Popular Hot Sale Hand Push Corn Planter Seeder Corn Planter by Hand Beans Planter Seed Drill

>> Summer Anti Bacterial Mens Colorful Short Basic Casual Breathable Cool Cotton Stripe Block Trainer Liner Socks

>> Wholesale Custom Bamboo Box, Square Small Solid Bamboo Wooden Gift Boxes with Lid

>> OGM series Electronic Flowmeter Toshniwal Flow Meter Oval Flow Meter Japan

>> Diamond Blade, Electroplating Blade, Cutting Granite / Marble

>> Summer Toys Plastic Big Pump Water Gun Toy for Kids

>> High Quality Chinese Truck Bus Auto Spare Parts Yutong Diesel Engine Fuel Injector 1112-00214

>> Cheaper Roll Paper Gluing Lamination Machine with Band Saw

>> Most Popular 5 Rows Corn Harvester Corn Harvesting Machine Farm Combine Harvester for Maize

>> 1.8 Ton Earth-Moving Machinery CE Crawler Hydraulic Cheapest Mini Excavator

>> China Factory Supplier Vertical Radial Drilling Machine (Z3035X10)

>> Fwincnc Pulse Fiber Laser Cleaning Machine Rust Remover Portable Laser Cleaner

>> CNC Loading and Unloading Soft and Hard Package Saw Blade Engraving Machine Cabinet Four Processes Plus Saw Blade Cutting Machine

>> Hzs50 Concrete Batching Plant 50m3/H Manufacturer Concrete Batch Plant Used for Road Construction

>> ABB TP830 brand new in stock with one year warranty at@mooreplc.com contact Mac for the best price

>> Physical-Therapy-Equipment Medical-Equipment Tens Products

>> Waterproof Army Style Camp Camouflage 3.5kg Below Zero 20 State Reserve Emergency Green Military Style Sleeping Bags Winter Troops Style Relief Camping Bag

>> Universal Automatic Drill Press 16/25mm (JZB-16/JZB-25(A))

>> 3D Sign Letter Making CNC Channel Letter Automatic Bending Machine

>> School Pencil Case Pen Bag Kids Pen Pouch Portable Stationery Bag

>> Popular Metal Storage Metal Base Steel Warehouse Roll Container

>> Car Oxygen Sensor 18213-54lb0 D19AA D20AA for Audi BMW Ford Nissan Renault Skoda

>> PU Leather USB 2.0 Flash Jump Drive 8GB 4GB 2GB 1GB

>> 50g - 500g Mix nuts / granule spice / sugar sachet automatic Snacks Packing Machine

>> Scb12-30~2500kVA/10kv Type Cast Resin Dry Type Power Electric Transformer

>> Automatic Peek material product edge trimming machine Ultra Shot NS-180T

>> Glass Roof Sliding Window Sunroom Garden Thermal Break Double Glazed American Style Sunroom