Wind Turbine Main Shaft CNC Turning and Heavy Machining Custom Steel Parts

| US$880.00-1,200.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

large

Output Type

AC Three Phase

Number of Blade

Multiple-Blade

Rotating Shaft

Horizontal

Stress Way of Blade

Resistance

Power

>100kW

Phase

Single-Phase

Certification

CE, ISO

Type

Crankshaft

Core Components

Shaft

Structure

Eccentric

Coatings

Custom

Model Number

OEM

Heat Treatment

Anneal, Quenchining & Tempering

Warrantyt6 Months Applicable Industries

6 Months

Transport Package

Export Package

Specification

large

Trademark

Totem

Origin

China

HS Code

8483109000

Production Capacity

100PC/Year

Packaging & Delivery

Package Size

180.00cm * 90.00cm * 90.00cm

Package Gross Weight

80.000kg

Product Description

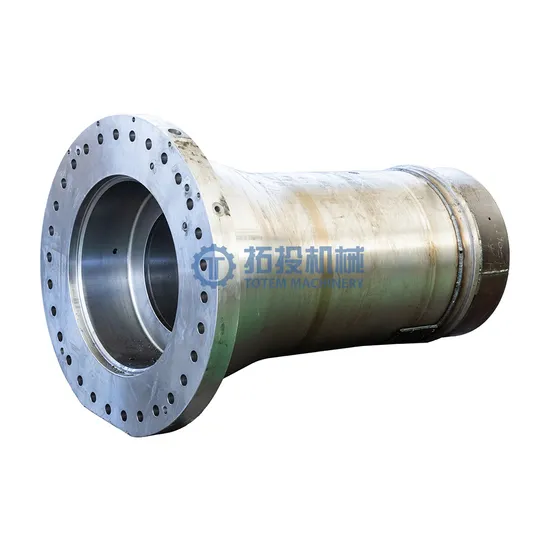

Product DescriptionWind Turbine Main Shaft CNC Turning and Heavy Machining Custom Steel Parts High-Precision Wind Turbine Main Shaft CNC Turning & Heavy Machining Services - Custom Steel Parts for Renewable Energy

Looking for a reliable and experienced manufacturer for Wind Turbine Main Shafts and other custom steel parts? We specialize in CNC turning and heavy machining of high-quality steel components, designed to meet the demanding requirements of the wind energy industry.

Precision CNC Turning: Our advanced CNC machining technology ensures tight tolerances and superior surface finishes for wind turbine main shafts and other critical components.

Heavy Machining Expertise: We handle large-diameter, heavy steel parts with precision, making us a trusted partner for wind turbine manufacturers.

Custom Steel Parts: From forged steel to alloy steel, we provide fully customizable solutions tailored to your specifications.

High-Quality Materials: We use only the best-grade steel to ensure durability, strength, and performance in harsh environments.

Competitive Pricing: As a leading China manufacturer, we offer cost-effective solutions without compromising on quality.

ISO-Certified Production: Our state-of-the-art facilities are ISO-certified, guaranteeing consistent quality and reliability.

OEM Services: We support bulk production and OEM orders, delivering on time and to your exact requirements.

Detailed Photos

Applications:

Wind turbine main shafts

Renewable energy machinery

Heavy industrial equipment

Gearbox components

TOTEM Service

TOTEM Machinery all the time works to supply GEAR SHAFT, ECCENTRIC SHAFT, HERRINGBONE GEAR, BEVEL GEAR, INTERNAL GEAR and other parts for transmission device & equipment (large industrial reducer & driver). Which mainly use to industrial equipment on fields of port facilities, cement, mining, metallurgical industry etc.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality suppliers' network, to let customers worry-free purchase.

TOTEM Philosophy: Quality-No.1, Integrity- No.1, Service- No.1

24hrs Salesman on-line, guarantee quick and positive feedback. Experienced and Professional Forwarder Guarantee Log. transportation.

We have different specifications of oil forging presses,ring rolling machines,electric arc furnaces,thus we can provide variety of forging,casting and welding materials according to customer's requests.- Large capacity, completed variety of quenching medium: oil,water,salt water,water based mixture.

Advantage of our Heat Treatment:- Professional, specific furnace, single-minded- Vertical pit furnace,keep the temperature uniformity during heating,+/-1°- Small deformation,little oxide layer,reduce material cost- Different materials can be cooled at the best speed

Strictly quality inspection system can produce high quality products. For each order,we can provide report for material chemical components testing,UT testing, hardness, mechanical property testing(impact testing,yield strength testing,tensile strength testing),size inspection,etc.

Customer Inspection & Shipping

Our products have been exported to abroad for more than 10 years and 50+ countries,such as America,Australia,Russia,Pakistan,Thailand,Indian,Morocco,Romania,Spain,etc.

In order to avoid the finish products rusted and damaged during the transportation ,we will design the right packing according to the shape,size and usage of the products. Contact TOTEM

Shanghai Totem Machinery Co.,Ltd

Facebook: Shanghai Totem

FAQ

What's TOTEM product processing progress?

Drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

How about TOTEM's export package?

Spray anti-rust oil on Herringbone Gear Shaft, Wrap waterproof cloth around Gear Shaft for reducer, Prepare package by shaft shape&weight to choose steel frame, steel support or wooden box etc.

Could I customize gear\gear shaft on TOTEM?

We supply customized Gear Shaft,Eccentric Shaft,Herringbone Gear,Internal Gear,Bevel Gear with big module, more than 1tons big weight, more than 3m length, forging or casting 42CrMo/35CrMo or your specified required material.

Why can I choose TOTEM?

TOTEM has 24hrs Salesman on-line, guarantee quick and positive feedback.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality supplier's network, to let customers worry-free purchase.

Experienced and Professional Forwarder Guarantee Log. transportation.

>> Mini Size 5y Battery Smoke Detector Compliance with En14604

>> Meetyou Machinery Grey Plastic Cable Trunking Profile Production Line High-Quality China PVC Stable Extrusion PVC Trunking Extrusion Machine Supplier

>> modern america aluminium vertical sliding window

>> Industrial Water Treatment Filter Vertical Automatic Self Cleaning Filter for Waste Water/River Water

>> Factory Price Square Glass Panoramic Elevator Lift for Shopping Mall

>> 200tph Good Quality Used Cone Crusher

>> 11kv High Efficiency Compact Power Solution for Industrial Use Dry Type Transformer

>> 1000KGS 1500KGS Full electric roll lifter rell lifter roll stacker

>> Casual Leather Belt Casual Dress with Single Prong Buckle (35-18234)

>> 12V 175A Auto Parts Car Alternator for Mitsubishi Lester 11590 11684 A3tx0692

>> Taijia JY-8ST Integrated Steel rebar scanner locator concrete cover thickness tester

>> Best Price Feed Additive L Lysine Sulphate Supplements Nutritions 25kg Amino Acid

>> Premium High Nickel Tungsten Carbide Roll for Industrial Casting Needs

>> Men′s Summer Mesh Loose Type Air Conditioning Large Size Quick Dry Pants

>> Mirror Polishing Enameled Silks Yarn Jump Preventer Stainless Steel Pulley

>> Professional Breathalyzer Factory Sale Alcohol Tester Car Alcohol Detector

>> 1-21410-795-0 1-21410-829-0 1-21410-831-0 6SD1 10PE1 Engine Cooling Radiator for ISUZU Truck GIGA 1999

>> Chrominum Picolinate Organic Chromium Chromium Salt Animal Feed Additive

>> Wedge Expansion Concrete M10 Stainless Steel Anchor Bolt

>> Plastic Extrusion Blow Molding Machine

>> Medical New Design Seven Functions ICU Motorized Hospital Bed with Thrombolysis Function

>> Hot Sales Mini High Efficiency Gasoline Diesel Power Tiller Machine

>> Used Caterpillar E200b Crawler Excavator Used Excavator Cat E200b Hydraulic Excavator

>> Taijia non-destructive rebar detectors for concrete rebar locator rebar detector finder

>> Manufacturer Food Additives Chemical High Quality Potassium Tripolyphosphate Ktpp

>> 1080P PTZ Home Monitor WiFi Camera

>> Anionic Styrene Acrylic Polymer Emulsion for Water-Based Paint

>> China Walnut Factory Wholesale Price Bulk Shelled Walnuts and Walnut Kernels

>> UGS2S 2 Color Table Top Small Mini Automatic Flexo Label printer, Flexographic Satin Printing Machine

>> 160kw 115-220t/H China Hpt200 Cone Crusher Stone Crushing Machinery Small Rock Crusher Price