Paint Mixer Manufacturer Paint Mixing Machine Industrial High Speed Disperser for Paint Industry

Basic Info.

Model NO.

High speed disperser

Application

Liquid with Suspended Solids, Powder, Viscous Fluid, Liquid, Granules

Application Area

Chemical

Certification

CE, ISO

Condition

New

Mixing Drum Shape

Conical

Stirring Type

Spiral

Working

High Speed Mixer

Control Type

PLC

Power

220kw

Speed Adjustment

Frequency Converter Control

Capacity

20-10000L

Mixer Type

Agitator

Layout Type

Horizontal

Operating type

Continuous Operating

Warranty

1 Year

Transport Package

by Sea

Specification

300

Trademark

JCT

Origin

China

HS Code

8474320000

Production Capacity

500 Pieces/Year

Packaging & Delivery

Package Size

180.00cm * 100.00cm * 90.00cm

Package Gross Weight

500.000kg

Product Description

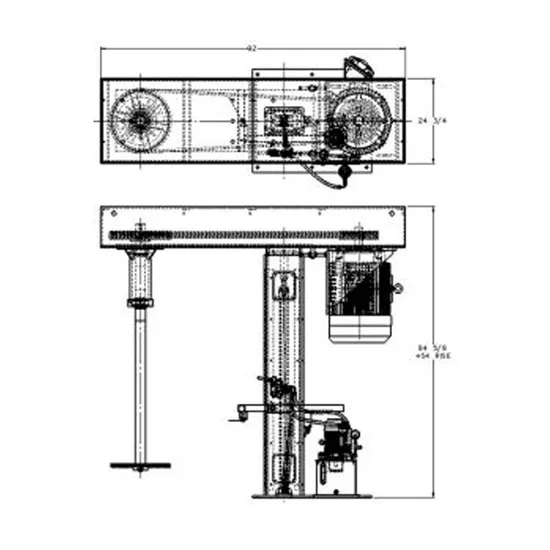

Product Description High Speed Disperser| Model | JCT-1.5 | JCT-4 | JCT-7.5 | JCT-11 | JCT-15 | JCT-18.5 | JCT-22 | JCT-30 | JCT-37 | JCT-45 |

| Motor power (kw) | 1.5 | 4 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 |

| Speed | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm |

| Disc dia(mm) | 120 | 200 | 230 | 250 | 280 | 300 | 350 | 400 | 400 | 450 |

| Production capacity(L/batch) | ≤60 | ≤200 | ≤400 | ≤500 | ≤700 | ≤800 | ≤1000 | ≤1500 | ≤2000 | ≤2000 |

| Hydraulic power(kw) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 1.1 | 1.1 |

| Lifting(mm) | 600 | 900 | 900 | 900 | 900 | 1100 | 1100 | 1100 | 1600 | 1600 |

| Weight(kg) | 400 | 600 | 800 | 1000 | 1100 | 1300 | 1400 | 1500 | 1600 | 1900 |

High speed disperser blades High speed disperser application scenarios

Recommended Products Company Profile

The JCT machinery has been producing industrial mixing, dispersing, kneading.blending and drying for over 15 years since 2006. We take 'make the mixingmore easier' as our belief and purpose in order to increasing the durability anoapplied in varius industries including cosmestics, chemical, plastics, batteryslurry, inks, pharmaceuticals, platics, adhesives, sealant, electronic pastes andglues etc.

We design and customise for every unique project by starting with 3D craftexposion, Our reliable team of engineers, sales managers, marketing andproduct analyzers are always ready for solving your inquiry and question onapplications.

JCT machinery now has over more than 10 product lines are ready for helpingyou find out best solution of your project including, silicone sealant, hot meltglue, battery slurry, rubbers and paint etc.

Our Partner Packaging & Shipping FAQ

>> 2 Drum 27gal/105L Sump Capacity Forklift Pockets HDPE Plastic Oil Barrel High Profile Spill Containment Pallet for Chemical Storage Leakproof

>> 6 Inch Kids Go Karts off Road Stable Electric UTV

>> Reliable High Response New Style Servo Energy-Saving Plastic Injection Molding Machine for PVC Fittings Hxm428-PVC

>> File Folder Carry Oxford Document Storage Bag with Zipper

>> 100t 3200mm CNC Press Brake Cutting Fold Bend Machine for Sheet Metal Bending Folding

>> 24.5 Inch 4K Ultra-Wide Stretched Bar Type LCD Monitor for Commercial Advertising Display

>> Industrial Two Stage Pusher Centrifuge for Salt Dewatering Needs

>> Industrial Machinery CNC Desktop CNC Plasma Metal Cutting Machine Steel Plate Cut Cutter

>> Custom Logo Luxury Eco Friendly Paper Mailer Packaging Boxes for Postal Cloth Bra Printed Blanket Corrugated Paper Shipping Box

>> Factory New Stylish Fashion Sport Trainers Jordan′ss Mens Casual Shoes

>> Industrial Water Filter Automatic Backwash Pressure Sand Filter Quartz Sand Media Filter for Seawater Desalination Water Treatment/Drip Irrigation System

>> Popular Mineral Processing Mining Stone Grinding Ball Mill Machine For Sale

>> IQF Frozen Cherries: Lock in Freshness, and More!

>> Hot-Selling Elegant Rainow Stones 925 Sterling Silver Necklace

>> Heavy Truck Cooler 16041-E0050 for Hino 700 Truck Radiator

>> Desktop Cable Fiber Laser Metal Marker Machine

>> Overdoor Fan Centrifugal Air Curtain Keeping Indoor AC Cooling Air

>> Custom Gold Hand Shaped Puller

>> Gold Accent Logo Gold Stamping Vegan Leather Cosmetics Bags Make up Bag

>> Slitting & Cut to Length Machine for Steel Pipe Industry Zscl-12mmx1650mm

>> LGP400/80pl-E China Famous Brand Grout Mixing Plant

>> Byloo soft bionic loach red head metal fishing lures

>> Good Quality Soundproof 3D PE Wall Foam Sticker

>> Factory Supply Honey Boost Energy Drink with Custom Printing Cans

>> Jkm-3500 Mini Mobile Self Loading Concrete Mixer Truck Cement Mixer Pump Price Portable Diesel Self Loading Concrete Mixers Factory Prices for Sale

>> China Manufacturer OEM Service R410a 12000BTU 1Ton Climatiseur 12000

>> 500ml Vacuum Mugs Thermos Sealed Stainless Steel Coffee/Tea Mug

>> Hot Selling Waste Plastic Pyrolysis Machine Price for Generation Electricity

>> Yeebo Chamomile Essence Moisturizing Skincare Thin Disposable Baby Diaper/Nappy

>> Factory wholesale luggage electric tailgate optional foot sensor for Nissan KIcks