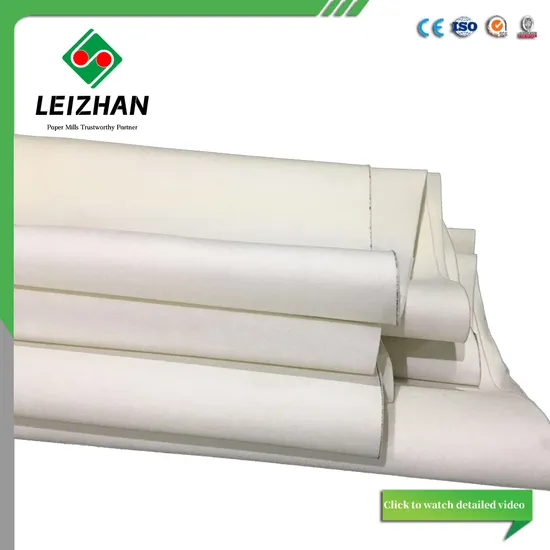

Endless Seamless Paper Machine Felt for Medium

| US$9.00-100.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LZPMC

Certification

RoHS, ISO 9001:2000, ISO 9001:2008, CE

Surface Treatment

Heat Setting

Manufacturing Process

Woven

Material

Polyester

Machine Speed

Below 2000m/Min

Layer

1/2/3

Paper Kinds

All Kinds of Paper

Srtucture

Woven and Needling

Transport Package

Standard Seaworthy Package

Specification

customized

Trademark

LEIZHAN PMC

Origin

China

HS Code

5911

Production Capacity

50000sets/Year

Product Description

Product Description Paper-making press felt can be divided into three types: wet press felt, pick-up felt and dryer felt according to the uses.Paper-making felt possesses good air permeability, mark-less, heat resistance, wet resistance, anti-aging, structure stability, anti-worn out, dimensional stability, excellent tensile strength, high linear pressure, easy to operate, long life performanceCustomizable:According to the paper machine and paper, we can change the structure of the base mesh. It has the characteristics of anti-high pressure, good elasticity and filterability, stable size, small elongation, great strength, and effective in eliminating grooving, vacuum marks, blind-hole marks, and other marks. Suitable for vacuum presses, kinds of complex presses, and other presses for producing grad offset paper, and kinds of high-grade paper and paper board, etc.

Detailed Photos

Product Parameters

| Single layer | Single layer forming BOM felt | Working speed | ≤800m/min |

| Single layer press BOM felt | Paper kind | all kind | |

| Single layer top BOM felt | Line pressure | ≤80KN/m | |

| Double layer | Double layer forming BOM felt | Working speed | ≤1000m/min |

| Double layer press BOM felt | Paper kind | all kind | |

| Double layer top BOM felt | Line pressure | ≤60-200KN/m | |

Triple layer | Triple layer BOM for large roll press | Working speed | ≤1000m/min |

| Triple layer BOM for shoe press | Paper kind | Newsprint, culture paper, high - grade board card paper | |

| Triple layer BOM for hot press | Line pressure | ≥ 200KN/m |

You may be interested in the following products too:

Leizhan Production Base

Company Profile

>> aluminum frame glass louvre windows/shutters with louvres with Glass Louvres window Frame System

>> Precision CNC Machining for Complex Parts Custom CNC Machining and CNC Milling Part Solutions

>> Paper sheet cutter roll to sheet paper cutter

>> FUJI Hairline Stainless Steel Passenger Elevator Lift

>> High Precision T Beam Drilling Machine for Metal Processing

>> Opposite Double Spindle CNC Lathe Turning Center of MW20

>> Green Red Eucalyptus Grass Wall Plastic Hanging Green Wall Panels Plants Decor

>> FTTH Fiber Optic Cable Stripper Alcohol Bottle Splicing Tool Kit

>> Wholesale Facotry Windshield Wiper of Goodyear (Patent support)

>> IC698CHS009 GE After sales service of rack nine hole base

>> HC-D003 High Frequency Low Price Portable Digital X-Ray Machine For People use

>> 5 Axis and 4 Axis High Presion CNC Milling Machine

>> Auto Parts Modified Hilux Revo Rocco Body kit 2018 upgrade to T-RD Version Body kits

>> 4G WiFi Repeater Signal Booster UTP FTP Cat5 CAT6 Internet Communication Cable

>> Hot Sales Electric Obstetric Gynecology Birth Baby Foaming Mattress Delivery Table or Ldr Bed with Foot Rest

>> Neoprene Neck Strap with Control-Stretch System for Dslrs and Binoculars

>> Sport PE Plastic Machinery for Snapback Cap Board Visor Cap Hat Brim

>> Outdoor Chilly Tub Portable Cold Plunge SPA Pool for Cold Water Therapy

>> Security wire mesh stainless steel window screen mesh

>> Precision Brass CNC Machining Fittings Brass Fittings

>> Nidec Kds-Villa Ladder Traction Machine for Passenger Elevator/ Home Lift

>> Industrial Tank Glass-Lined Closed Tank /Horizontal Type Distilling Reaction Mixing Storage Tank 30000L

>> Baldan Fishing Type Disc Plough

>> Multi-Purpose Foldable Adjustable Ab Sit up Bench

>> Processing Machines Animal Feed Pellet Feed Pallet Making Machine Animal Feed Pellet for Pellet Machine Fish

>> New Energy Charger Aluminum Alloy Die-Cast Shell Radiator Shell

>> Double-Shaft Feed Mixer (SSHJ) Best Selling Mixer

>> OEM&ODM Free Sample Tian Jiao Wholesale Disposable Baby Diaper Manufacturer

>> 4 Axis Double Column Machining Center Gantry Type Machining Center Gl4022

>> Custom Metal Cutting Machine Accessories Worm Gear Worm Shaft