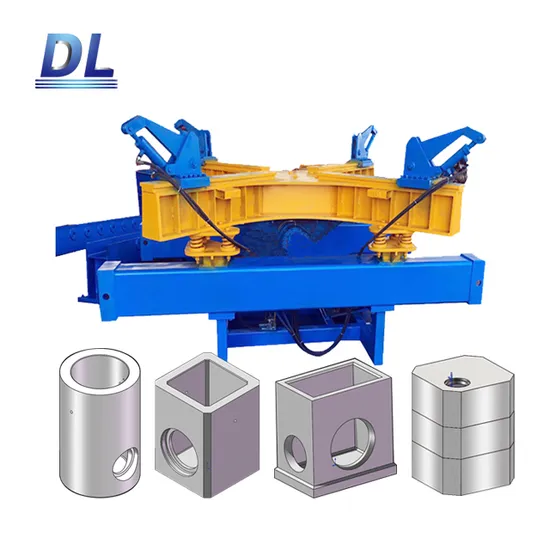

High Quality Concrete Manhole Forming Machine, Concrete Manhole Well Equipment

| US$80,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

4000*4000

Pipe Material

Concrete

Condition

New

Customized

Customized

Theory

High Frequency Vibration

Application

Industry

Type

Pipe Production Line

Shaping Mode

Preform Mould

Maximum Product Specification

2200*2200

Use Purpose

Making of Concrete Manhole Well

Mold Plate Thickness

According to The Mold Specification Size

Transport Package

Standard Export Packing

Specification

customization

Trademark

DL

Origin

China

HS Code

3714965129

Production Capacity

100set Per Year

Product Description

Product Description1. The dry hard concrete are vibrating formed through the higher exciting force of high frequency vibrator(5000~6000rpm). No need steam curing, instantly demold, save energy and envioronment protection.

2. Manhole body and manhole pedestal are connected and formed one time.The manhole pedestal are upper when vibrating production.solve the two times formed problems of traditional production technology.

3. This high frequency vibrating table(5000~6000rpm) will make whole precast products longitudianl vibrating. The whole manhole body and manhole pedestal's vibration are evenly, higher compactness. Less pores.

4. The manhole mold automatically turn over through the mould's axial eccentric force. Manhole pedestal are under and demold. Then the manhole petestal won't occur collapse,crack and seepage ect situations.improving the production efficiency.

5. Operation simple, Highe versatility, which could produce round manhole, rectangular manhole, U channel, concrete pipes etc all kinds of shaped precast proudcts.

6. High frequency vibrating table adopt high performance spring damping,Upper vibration amplitude transmission effect is good, Below damping effective good. Detailed Photos

High frequency vibrating table manhole machine

High frequency vibrating mahole machine produced products

Product Parameters

Water absorption rate experiment: 1.15%

Concrete absorption rate experiment data sheet:

| Concrete part | Quality after drying(kg) | Quality after absorption(kg) | Water content(kg) | Absorption rate(%) |

| Upper part | 4.595 | 4.620 | 0.025 | 0.5 |

| Lower part | 4.505 | 4.550 | 0.045 | 1.0 |

| Middle part | 4.695 | 4.800 | 0.105 | 2.2 |

| Concrete | 4.53 | 4.570 | 0.040 | 0.9 |

Certifications

Packaging & Shipping

Company Profile

Gaotang Dingli Construction Machinery Co., Ltd. was founded in 2010,Dingli is professional in making high frequency vibration concrete pipe machine, vibration manhole machine, vibration box culvert equipment and other precast product molds. With the unique design and the creative designers' working, Dingli has achieved more than 30 patents of innovation, and has also been honored as the R&D center of technological enterprise of Shandong Province, one of the top ten best innovative enterprise in Liaocheng city and won the award of innovative prize of concrete product technology.

Based on the independent R&D design ability, we could work out the most competitive and innovative equipment for our client. With our 30 years experiences in concrete product and equipment manufacturing, our 100 employees have been making durable equipment that used for underground pipeline and sewer system. The high-quality equipment is exported to south-east Asia, Africa, mid-east, more than 30 foreign countries.

We aimed at making humanized and innovative equipment, take the win-win as our principle, adopt the perfectioinism QC system, and develop the best aftersales service to bring the bright new future for each of our client.

Our Advantages

1. with many years of industry experience

With professional design, production, quality management, after-sales service and other teams of continuous improvement equipment, as an outstanding enterprise in the industry, we have been adhering to the learning is the ladder of progress.

2. Production chain

Reasonable production chain, can be more efficient production, greatly shorten the production cycle.

3. Product quality

The use of high-quality raw materials processing and production, strict quality testing, to ensure product life.

After Sales Service

Different kinds of products are available in our company. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective!

>> Hot Selling Portable MIni Usb Air Cooler Mist Ultrasonic for Car/Household/Home/Office

>> Rth-1400A4 Label A4 Paper Sheeter Kraft Paper Roll Sheet Cutting Machine with Two Frame

>> Toilet Tissue Paper Making Kitchen Towel Paper Making Machine

>> Drilling Tapping Machine Power Head by Professional Manufacture Servo Head Unit

>> High Configuration Electric Silicon Steel Transformer Core Cutting Line

>> Luxury Rigid Phone Case Box with Custom Logo Branding

>> PS12S double layer ripple wave wall paper glass cup making forming machine with automatic lubrication system

>> CB Antenna Radio 27MHz Antenna Heavy Duty Magnet Mount

>> Fedjet Advanced Accurate 3/5 Axis CNC Waterjet Cutting Machine

>> High Cutting Speed Servo Wirecutting EDM Machine Hq-630GS

>> Elegant Minimalist Stainless Steel Bathroom Cabinet with Antibacterial and Mold-Proof Features

>> Custom Design Packaging Bag Plastic 14G Mylar Bags Print Packag

>> 2022 Men's Customized Sublimation Singlet of Green Leaves Pattern

>> Compact Metal Dish Drainer Rack With Drainboard and Utensil Holder Set, 12" x 19" x 5\

>> Heavy Duty Construction Hoist Lever Chain Block with Hook

>> TR1160 Timing Chain Kit Automotive guide rail for MERCEDES-BENZ OM 668.914/OM 668.940 with oe no.:6680520316;A6680520316

>> Cordless Drill Rotating Charging Screwdriver Hand Drill

>> Radial Drilling Press Machine Z3040X13

>> 33 Joules Soft Body Armour Clothing Stab Proof Vest

>> Bull Bar Rear Bumper for Toyota Prado Fj120 2003-2009

>> Rocky Buffalo Orange Black Sport Model Steel Toe Safety Shoe Steel Middle Sole with PU/PU Outsole

>> Used Zoomlion Elevator Building Hoist and Lifting Equipment

>> Auto Parts 5wk96653c A0101539528 A0091530028 A0091539528 Nox Sensor for Diesel Engines

>> Proficient Waste Tire Rubber Recycling Machine with Crusher

>> 1799 skmei wholesaler quartz watch reloj hombre lujo rose gold diamond womens waterproof watch for lady

>> Modern Pendant Light with ETL Certification for Stylish Spaces

>> Oil Well Downhole Overshots Releasing and Circulating Overshot

>> Customized Granulation Screw Barrel with High Capacity for Recycled Material 1

>> Wholesale Price Badminton Products Professional Badminton Nets

>> Chicken Farm Feed Pellet Dryer Feed Cooler Sheep Feed Pellet Cooling Machine