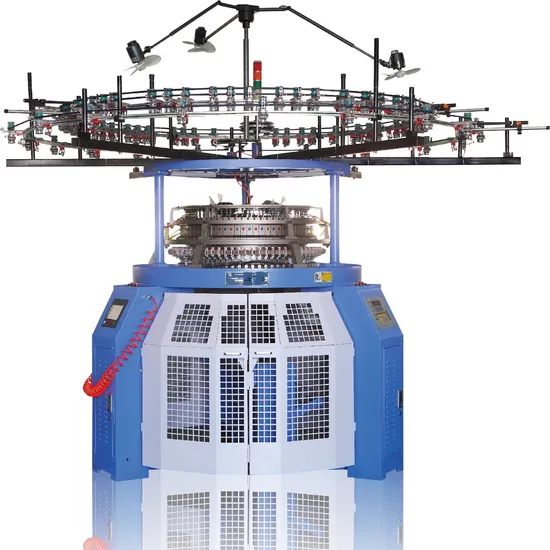

Single Jersey 3-Thread Fleece Jacquard Circular Knitting Machine

| US$30,000.00-34,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

RSDT-D/W3

Knitting Machine Cut

E20

Knitting Style

Weft

Knitting Method

Single

Needle Style

Latch Needle

Needle Bar Style

Circular Knitting Machine

Computerized

Computerized

Condition

New

After-sales Service

Installation, Operation Training

Cylinder Diameter

30"~38"

Gauge

18g~20g

Feeders

42f~60f

Origin

China

HS Code

84471200

Production Capacity

100 Sets Per Month

Product Description

Type:

This is a computerized jacquard machine for three-thread fleece.

Features:

It equipped with electronic needle selection in the cylinder, any complex textrue can be knitted.

The desigh data can be conveniently inputted and stored via USB device.

The heart parts of the machine.

Convertible into single jersey jacquard machine by change the cams.

Product Parameters

Technical data:

| Machine Type | Single Jersey With Electronic Jacquard |

| Function Device | Electronic Jacquard |

| Cylinder Diameter | 30" ~ 38" |

| Machine Gauge | 18G ~ 20G |

| Feeders | 42F ~ 60F |

Product Application

Structrues:

This machine can knit most kinds of three-thread fleece fabric with jacquard pattern.

Application:

Applied in multiple fields such as sports & leisure, ourwears etc.

Our Advantages

High Manufacturing Capacity:

Annual production of 1500 ~ 2000 circular knitting machines and related accessories.

Advanced In-House Manufacturing:

Our factory is equipped with high-precision machinery, including gear hobbing machines, CNC machining centers, and CNC vertical lathes from Germany and Japan. By producing all core components in-house, we maintain strict quality control and ensure exceptional precision, resulting in superior machine performance.

Premium Materials for Durability:

We insist on using high-quality steel and alloy materials for all components. This commitment to premium materials significantly extends the machine's service life and enhances durability.

Cutting-Edge R&D and Engineering:

With our dedicated research and development center, experienced design engineers, and skilled technical team, we continuously refine our technology. As a result, our machines deliver higher precision, allowing you to knit superior-quality fabrics with greater efficiency.

Quality Service:

Our professional team provides pre-sales and after-sales services such as product consultation, technical guidance, installation services, and operation training.

Production Equipment

Core Component Processing

>> ABS PS PC PP PE Plastic Waste Household Appliance TV Shell Recycling Machine Line with CE Certification

>> Needle Type Chlorine Cylinder Valve QF-10 / Brass valve with 316L stem

>> 350/355/400 mm Big Size Cutting Disc for Metal/Stainless

>> Silicone Self-Adhesive Windproof Waterproof Door Bottom Seal Strip

>> Motorcycle Bike Front Fork Shock Absorber Jd90 Dayang

>> 14K Solid Gold Lab Grown Diamond Micro Pave Wedding Ring 1.50 mm Ring Gold Wedding Band Full Eternity Stacking Ring by G

>> Witch with Pumpkin Pot Halloween Decoration Resin Craft

>> Customized Restaurant Furniture Modern Leisure Dining Room Furniture Wooden Nordic Dining Chair

>> Fanuc System CNC Two Head Milling Machine OEM-Machining Plate Double Head Milling Machine Manufacture-Finished Plate Duplex Milling Machine Purchase

>> The customized aluminum profile of sunshine room is resistant to high temperature and is not easy to scratch

>> Road Freight From China to Russia, Door to Door Shipping

>> Ck6140 0.5/1/1.5/2/3m Hydraulic 3 Jaws Chuck and Tailstock Horizontal Flat Turning Lathe with Siemens/GSK/Fanuc System

>> Stand up Paddle Board and Longboard with Customized Design

>> Industrial Modem Support Lte Tdd. B41 UMTS. B1, B6, B8

>> 6 Ton Excavator Attachments 6000nm Earth Auger Drill Machine

>> Domestic Waste Recycling Complete Machinery for Rigid Crushed PP Like Chairs, Crates, Household

>> Kdsbuilding Indoor and Outdoor Black and White Double Pane Thermal Insulation Glass Sliding Door

>> Nr-1325 Furniture Manufacturing Equipment 3D CNC Router Wood CNC Router Machine

>> Wood Acrylic CNC Laser Engraving Cutting Machine Laser Cut Machines

>> Multi Colors Full Servo UV Screen Printer Italy Wine Bottle Screen Printing Machine for Jar Beer Glass Wine Bottle

>> Rubber Recycling Machine Tire Recycling Machine Tire Recycling Machine

>> Halo Combat Evolved Swords 69cm

>> High Efficiency Vertical Paddle Mixer for Heat Sensitive Product

>> 2kw Laser Cutting Machine Iron Steel Metal CNC Fiber

>> Customize Nanofiber Window Screen Wire Mesh with Frame

>> Theatre Church Activity Metal Can Stack Comfortable High Density Upholstered Church Chairs

>> Outdoor 24V/1000W 4 Wheels Mobility Four Wheel Heavy-Duty off-Road Electric Elderly Scooter Max Speed at 15km/H EEC Approval

>> Tri-Ring Right-Handed Drive Stq5189jsqn6 Boom Truck Cranes China Distributors Euro 2 Crane Truck

>> Timing Chain Kit TK2409 with oe no.53020681 53020779 53021168AA 53020781 53020910 for DODGE/JEEP/CHRYSLER 4.7L

>> Small Rescue CE Sport Speed 390 13FT 3.9m Aluminum Semi-Rigid Deep V Bottom Luxury PVC Hypalon Inflatable Rib Tender Dinghy Boat for Sale Factory