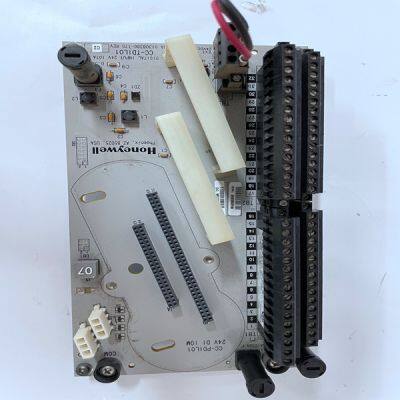

CC-TDIL01

Product Details

Product Details

Product Description

Product DescriptionBrand:HONEYWELL

Type:CC-TDIL01

Origin: the United States

Warranty: 365 days

Colour: new/used

Shipping method: Courier delivery

Module of PLC, DCS, ESD system card, the card is a vibration monitoring system, steam turbine control system module, the advantages of the gas generator spare parts brand: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, mechanical, electronic manufacturing, automobile manufacturing, plastic machinery, electric power, water conservancy, water treatment/environmental protection, boiler heating, energy, power transmission and distribution and so on.

An option is available to automatically halt the auto start sequence at the idle setpoints. This feature would result in the unit automatically stopping or halting at the low idle setpoint and at the high idle setpoint. If the unit is started and the speed is above the low idle setpoint, the sequence will initialize as halted. The sequence must be given a ‘Continue’ command once halted. The hold timers are still active with this option. If ‘Continue’ is selected and the hold timer has not expired, the sequence will remain in a timed wait until the hold timer has expired and then continue from that point. When the ‘Auto Halt at Idle Setpts’ option is programmed, the Auto Start Sequence Continue contact input only requires a momentary closure to continue the sequence. No Idle Programmed If neither the Idle/Rated or Auto Start Sequence functions are programmed, the speed setpoint will ramp from zero to the minimum governor setpoint at the ‘Rate To Min’ setting rate. Critical speed bands cannot be programmed with this configuration. Speed Control Overview Turbine speed is sensed through one or two MPUs or proximity probes. The ‘MPU Gear Ratio’ and the ‘Teeth Seen By MPU’ settings are configured to allow the 505E to calculate actual turbine speed. One MPU and one proximity probe can be used at the same time, however, they must be mounted on the same gear since the ‘gear ratio’ and ‘teeth seen by the MPU’ must be the same for both inputs. The 505E’s Speed PID (proportional, integral, derivative control amplifier) then compares this speed signal to a setpoint to generate an speed/load demand signal to the ratio/limiter (through a low signal select bus). NOTE The 505E is factory set (jumpers installed) to interface with passive MPUs, if proximity probes are used, the jumpers must be changed (see Chapter 2 for jumper options).

Speed PID Operational Modes The Speed PID operates in one of the following modes, depending on configuration and system conditions: 1. Speed Control 2. Frequency Control 3. Unit Load Control (droop) • Turbine HP and LP valve position control • Generator Load control Speed Control When not programmed for generator applications, the 505E Speed PID operates in a Speed control mode at all times. When programmed for generator applications, the state of the generator and utility tie breakers determine the operational mode of the Speed PID. If the Generator breaker contact is open, the Speed PID operates in a Speed control mode. If the generator breaker is closed and the utility tie breaker is open, the Frequency control mode is selected. When both the generator and utility tie breakers are closed, a Unit Load control mode is selected.

>> Single-Stage Emulsified Homogeneous Pump for Dairy Processing Cheese

>> Galvanized Steel Resistant Anti Slip Grip Strut Grating

>> EPC04 Phone Case Cover, Mobile Case Cover

>> Fine aggregate stone powder content tester

>> Yada Factory High Quality Wooden Toothpicks Bulk 10000pcs/box Cheap Wooden Bamboo Tooth Pick

>> Servo Motor and Driver High Efficiency

>> Manufacturer of High Quality Ulva Lactuca Algae Powder Bulk

>> 302 Illusion Bodice Spaghetti Straps Wedding Dress with Detachable Long Sleeve Bridal Gown Dress with Mermaid Skirt Dress by Manufacturer Bridal

>> 15X3mm 20X5mm Strong Neodymium Round Magnet with Countersunk N52 Screw Thread M3 M4 Hole

>> Quality Safety cast iron handwheel Lathe handwheel valve parts

>> aluminum auto radiator manufacturers for ISUZU truck 1-21410-674-1 8971771931 8973772380 8973543650 8-97371-010-0

>> Good Quality Three Point Mounted Disc Ridger for 20HP 60HP Tractor

>> Taijia concrete test hammer schmidt hammer concrete rebound hammer Hardness Tester

>> Diamond Saw Blade Welding Strength Testing Machine

>> Weldon Hot Sale Custom Stainless Steel Wall Metal Electric Junction Box

>> UGS62S 6 Positive 2 Reverse Double Side Automatic Garment Label Flexo Printing Machine, Cotton Webbing Flexographic Printer

>> Canvas and Leather Bicycle Water Bottle Cup Holder Bag Wine Carrier

>> High Quality Pure Pharmaceutical Grade Pullulan Powder

>> Complete and Desirable Liquid Nitrogen Producing Plant

>> Medical Orthopedic Surgical Broken Nail Screw Extractor Skid Screws Removal Instrument Set

>> Taijia magnetic digital water volume flow meter electromagnetic flowmeter electromagnetic flowmeter

>> Ohaus High Speed Microplate Shakers

>> Industrial Food Blender Candy Powder and Liquid Fertilizer Mixer Gypsum Mixing Equipment

>> Wall Display Advertising Snap Frame Clip Open LED Menu Board Light Box

>> Deling Versatile 500-1000L High Speed PVC Mixer Equipment with Hot Heating Cooling Mixing Machine for Waste Plastic Powder Particle Wet Resin Recycling

>> Oturncnc High Precision CNC Slant Bed Turning Lathe Ety800 High Precision Slant Bed CNC Lathe

>> Tube Mill Line for Carbon Steel Pipe Production

>> Tombstone Gravestone CNC Carving Machine 3axis/4axis 1300*1800mm

>> Funny Swing Monkey Candy Toy Promotional Toys Plastic Toys

>> High Quality Best Price Plug Plastic Injection Molding Machine