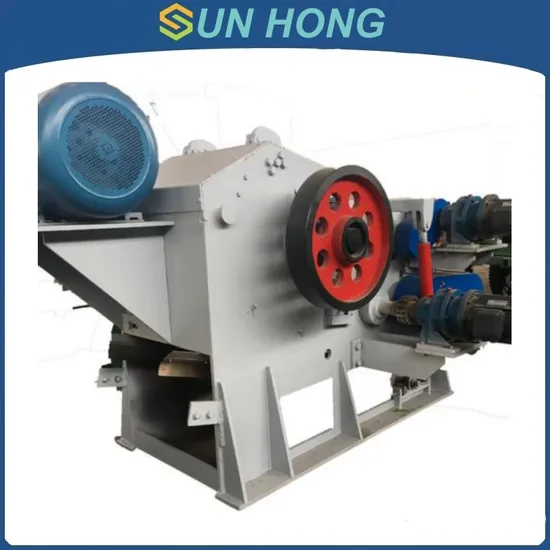

Paper Board Making Wood Pulp Processing Wood Chip Processing Drum Chipper

| US$2,000.00-5,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

Sun Hong

Automatic Grade

Full-Automatic

Warranty

1 Year

Quality

Top Level

Color

Customer Required

Advantage

High Efficiency and Low Consumption

Application

Preparing High-Quality Wood Chips

Transport Package

Wooden Box, Iron Frame

Specification

make to order

Trademark

SUN HONG

Origin

China

HS Code

8439990000

Product Description

Wood Drum Chipper

1. Drum chipper is a special equipment for preparing high-quality wood chips. It is suitable for paper mills, artificial board factories and wood chip production bases. It can cut logs, small-diameter wood, etc. into high-quality industrial wood chips with uniform length, smooth incision, and uniform thickness. It can also cut branches, boards, etc. In order to meet the different requirements for wood chip lengths in papermaking, fiberboard, particleboard and other industries, various drum chippers have been improved and designed; the new models are closer to users and have superior performance. They are ideal equipment for wood chip preparation at home and abroad.

2. After the raw materials are cut, they become small wood chips of a certain specification, which can be used as raw materials for particleboard, medium density board, fiberboard and other papermaking industries, and can also be used as fuel.

Working Principle

The wood is fed in through the feed port. When the wood comes into contact with the cutting blade of the drum chipper, it is cut with the high-speed rotation of the cutting cutter. The high-speed airflow generated by the fan blades is sent out.

Applied Raw Material

Finished Chipps

The Structure of Chipper Frame

It is welded with high strength steel plate, which is the supporting foundation of the whole machine.

Upper and lower feeding mechanism

It is composed of feeding interface, upper and lower feeding rollers and feeding gap adjustment mechanism. The wood entering from the feeding interface is pressed by the upper and lower feeding rollers and fed to the cutting mechanism at a certain speed to control the size of the cut wood pieces; when processing thick wood, it is adjusted by the feeding gap adjustment mechanism.

Hydraulic System

Supplied to the cylinder by the oil pump, the cover can be activated to facilitate the replacement of blades; the upper feed roller assembly can be lifted up during maintenance to facilitate the adjustment of the gap between the fly cutter and the bottom cutter and the dismantling of the comb plate.

Knife Roller

Two or three or four flying knives are installed on the knife stick, and the specially made bolts for flying knives are used to fix the flying knives on the knife roller through the pressure block.

Bottom Knifes for Drum Chipper

Technical Parameter

| Model | Drum Diameter (mm) | Feed Port (Height × Width) (mm) | Production Capacity (m³/h) |

| SH2110 | 1000 | 330×1050 | 75 |

| SH2113A | 1300 | 400×700 | 58 |

| SH2113/13 | 1300 | 400×1250 | 132 |

| SH2113/11 | 1300 | 400×1050 | 100 |

| SH2116/13 | 1600 | 600×1250 | 185 |

| SH2120/13 | 2000 | 800×1250 | 220-300 |

| SH2120/15 | 2000 | 750×1450 | 250-350 |

>> Automatic Flour Tortilla Standardise Production Line

>> 1m USB Type-C Pigtail Cable Extension Power Cable 22AWG 5V 3A

>> Portable 2oz Stainless Steel Drinking Wine Cup Coffee Mug with Straw

>> Recyclable High Quality Waterproof Packaging Four-Way Entry 3 Runners Type Rack Able Anti-Slip Easy to Clean Heavy Duty Hygeian Plastic Pallet 1200*1000*150

>> High Speed Film Blowing Machine PE Film Extruder for Plastic Bag

>> Air Cooling High Precision Mini Laser Machine 1500W 2000W CNC Portable Handheld Fiber Laser Welding Machine with Factory Price

>> Fit-3800d High Speed Singer Needle Chain Stitch Sewing Machine

>> Manufacturers wholesale a batch of disposable fragrant bamboo sticks

>> China Famous High Quality Road Safety Barrel Blow Molding Machine

>> Battery Charger for Lenovo Universal Laptop Adaptors 65W USB C Type C Power Adaptor Charger

>> Livefun Design High Voltage Commercial Industrial Solar Energy Storage Cabinet 100kwh 215kwh Ess Container Battery

>> Auto Parts 22680-37j00 Maf Mass Air Flow Meter Sensor for Nissan

>> High Purity Cobalt Metal- Pure Chromium Metal

>> 13.98-Meter Long 45-50ton Excavator Pile Driving Arm Has a Pile Driving Hammer Depth of 6-9-Meter for Zx360

>> PE, PVC, EVA, PLA Low Speed Waste Polystyrene Recycling Equipment Plastic Shredder Granulator/ Plastic Film Granulator

>> Pet Bottle Blowing Machine

>> Rated 200kw 250kVA Continuous 180kw Natural Gas Generator Set with CHP Cogenerator

>> Luxury Parquet Floor Tiles Wood Floor with Marble Floor Decoration

>> All Weather Cheap Roman Metal Line Outdoor Tent Gazebo Garden Pavilion

>> Lxda-200 End Milling Machine for Aluminum Profile End Milling, Step Face and Slotprocessing etc, at The Same Time Milling Multi-Piece Profiles

>> Hot sale bamboo toothpick making machine/wood toothpick machine production line

>> SHOOBB Heavy-Duty Mixing Truck DLQ5180GJBBJ6/China Distributors Right Handed Drive Cement Mixer Trucks

>> Top Luxury Royal Home Textile Grey Yarn-Dyed Comforter Quilt 100% Mulberry Silk Duvet Cover Four-Piece Coverlets King Size Bed Flat Sheet Pillowcase Bedding Set

>> 20L Plastic Knapsack Battery Pump Agricultural Garden Pest Control Sprayer

>> Upgraded Extra Long Range Smart Wireless Meat Thermometer 100% Waterproof Meat Thermometer for Oven Grill Smoker Cooking BBQ

>> Strong Absorption Water Mop Head Cotton Yarn for Floor Cleaning Mop

>> Tangchen 1 Year According to Design China Portable Mixers Concrete

>> Customized Sublimation Polo Shirt of Blue and White Colors with Short Sleeves

>> Euchips 15W Phase-Cut Constant Current Dimmable LED Driver for LED Lighting

>> Hone 150L Affordable Price Plaster Vacuum Mixer / Cosmetic Cream Production Line Machine for Making Lotion / Ointment