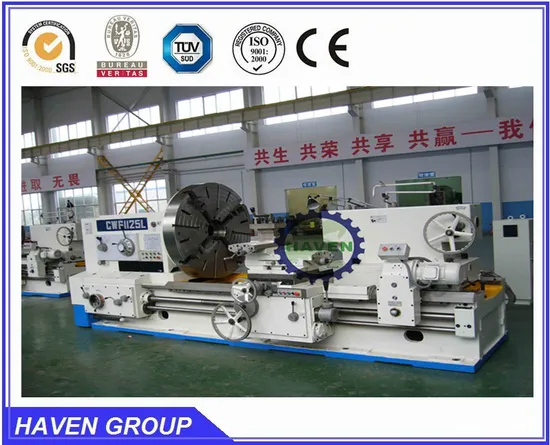

CW61160L Horizontal Heavy Duty Lathe

| US$100.00-100,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

CW61160L/2000

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Electric

Controlling Mode

Artificial

Automatic Grade

Semiautomatic

Setting Mode

Floor-type

Precision

Precision

Certification

CE, ISO 9001

Condition

New

Max.swing diameter over bed

1600mm

Width of bed

1100mm

Max.length of workpiece

2000mm

Transport Package

Wooden Pallet

Specification

CW61160L/2000

Trademark

HAVEN

Origin

China

HS Code

84581900

Production Capacity

100 Unit/Year

Product Description

CW61160L Horizontal Heavy Duty LatheMain features:

These lathes can perform to turn end-faces, cylindricl surfaces and internal holes of various parts as well as metric, inch, module and pitch threads.

The top slides can be operated individually by power for cutting short taper surface also, can be turned automatically through the compound movement combining longitudinal feed with the top slide feed, moreover, the machinery may be used for drilling, boring and trepanning.

They are characteristics of power, high spindle speed, high rigidity. The various ferrous and non-ferrous metals parts may be turned through the heavy cutting by carbon alloytools.

Main specification:

| SPECIFICATION | Model | |||||

| CW61125L | CW61140L | CW61160L | CW61180L | CW61190L | ||

| CAPACITY | Max.swing diameter over bed | 1250 | 1400 | 1600 | 1800 | 1900 |

| Max.swing diameter over crossslide | 880 | 1030 | 1230 | 1400 | 1500 | |

| Width of bed | 1100mm | |||||

| Max.length of workpiece | 1000 -8000mm | |||||

| SPINDLE | Spindle nose | A15 | ||||

| Sindle bore diameter | 130mm | |||||

| Taper of spindle bore | Metric No.140# | |||||

| Range of spindle speed | 3.15-315r/min 21kinds | |||||

| FEEDS | Longitudinal feeds range | 0.1-12mm/r 56 kinds | ||||

| Transversal feeds range | 0.05-6mm/r 56kinds | |||||

| Metrec thread range | 1-120mm 44kinds | |||||

| Inch thread range | 3/8-28TPI 31kinds | |||||

| Module thread range | 0.5-60mm 45kinds | |||||

| Pitch thread range | 1-56TPI 25kinds | |||||

| TAILSTOCK | Tailstock sleeve taper | Metric 80# | ||||

| Tailstock sleeve diameter | 260mm | |||||

| Tailstock sleeve travel | 200mm | |||||

| MOTOR | Main motor power | 30kW | ||||

| Rapid motor power | 1.5kW | |||||

| Coolant pump power | 0.125kW | |||||

>> Ra Desktop Magnetic Automatic Pick and Place Screw Fastening Equipment

>> Passenger Elevator Parts High Quality Passenger Elevator Traction Motor

>> HC-B014F A2000 Chroma machine Fluorescent quantitative POCT Hormones analyzer ichroma ii immunoassay test machine

>> Tension Control Bolt for Steel Structures

>> Factory Made 360 Degree Rotational Base Mini Electric Tea Water Kettle

>> Hot-DIP Galvanzied Steel Milking Parlor Airbag Flush Valve

>> Efficient Power Transmission with Hollow Chrome Drive Shaft

>> Hg 50 Carbon Steel High Frequency ERW Tube Mill Line for Welding Square Round Rectangle Pipes

>> Hot sale excellent quality paddy rice thresher /sesame thresher machine/wheat thresher

>> Medical Disposable Glucose Tube for Blood Collection Vacuum Tube

>> CNC Connecter Cutting Saw for Aluminum Profile Window and Door Processing

>> ISO9809-1 Oxygen Gas Bottle TUV 15L 150bar Ut Gas Tanks 37mn Tped Gas Cylinders

>> China Square Column Stand Vertical Drilling Machine Z5125 Metal Drilling Machine

>> Infant Nutrition Processor Nutrition Instant Powder Baby Food Processing Equipment Making Machine

>> Small Low Price Waste Mobile Plastic Bottles/Metal/Rubber Products Shredder Crusher Machine Scrap Wood/Glass Paper Metal Grinder Machinery

>> 1.14 Inch Magic Voice Changer Small Size Mini Cute Flip Mobile Phone L8star Bm60

>> 1500W Stage Effect Fog LED DMX Moving Head Disco Equipment

>> modern latest design solid wood soundproof interior doors for houses bedroom prehung walnut best flush single french wooden door

>> CNC Machine Tool Vmc1160 Vertical Machining Center High-Precision Vmc 3-Axis Lathe CNC Milling Machine

>> Gq50 Portablemanual Electric Hydraulic Rebar Cutter Pliers Tools Automatic Steel Bar Cutting Machine

>> High-Efficiency Growatt Hybrid Inverter 6000W MPPT for Solar System with Good Price

>> 5t Trolley Type Chain Hoist Electrical Lifting Equipment

>> OEM Lip Care Moisturizing Beauty Butter Lip Balm Hydrating Fruit Scents Lip Balm

>> Dortec Automatic Door Closer on Door

>> Automatic rubber deburring machine Ultra Shot NS-180T

>> Digital Display Compressive Strength Testing Machine Price

>> Polyester Nylon Velvet Suppliers Upholstery Fabric Chair Cover Cordury

>> Auto Backwash Plastic Disc Filter for Micron Irrigation System

>> Taijia concrete rebar steel locator scanner zd310 integrated rebar detector

>> N female jack crimp Connector Adapter Panel Solde n-type female 4-hole flange mount rf Conector N-conector coaxial 50ohm PCB