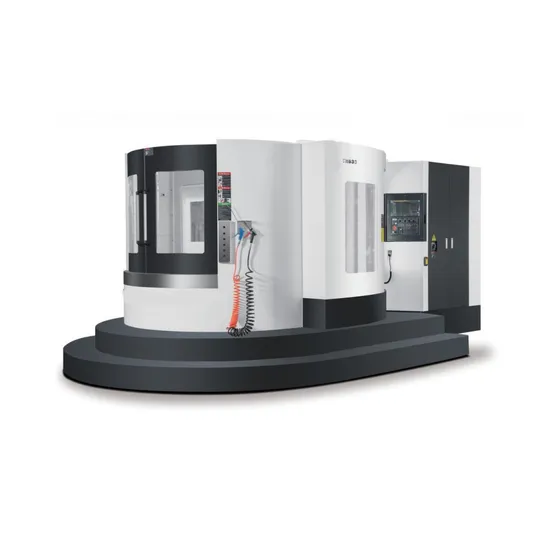

Horizontal Machining Center Series, High Efficiency, Machine Lathe

| US$5,000.00-50,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

TH-63S

Precision

High Precision

Certification

GS

Condition

New

Transport Package

Woodencase

Specification

6600x4300

Origin

China

Production Capacity

1000pieces/Year

Product Description

Product DescriptionDouble exchange rotary table, Save labor cost, High efficiency

TH-63S is equipped with double-exchange rotary table, which can realize workpiece loading and unloading on the outer table during machining, so that clamping and machining can be carried out simultaneously, reducing non-machining time and improving machine operation rate.

It has obvious advantages for machining parts with short processing time and frequent clamping, and greatly improves equipment utilization.

Processing examples:

X/Y/Z-axis travel: 1050×750×900 mm

X/Y/Z-axis rapid traverse:24/24/24 m/min

Worktable area: 630×630 mm

Spindle speed:6000 rpm

Product Features:

+The base adopts "T" layout, optimized by finite element analysis, and the arrangement structure of the cast tendon type, which improves the overall performance index and does not produce overturning torque in the whole stroke.

+Double exchange rotary table, high stability of operation, improve processing efficiency.

+Taiwan high precision spindle, standard speed 6000rpm, with spindle air curtain protection, stable precision and long life.

+Adopt high power constant torque motor.

+High rigidity roller guide structure, both the heavy cutting rigidity of hard rail and the fast moving characteristics of linear guide. +Screw double support pre-stretching, eliminating transmission backlash and pre-compensating the error caused by temperature rise.

+Precision rotary table, ultra-high positioning and repeat positioning accuracy to ensure workpiece processing accuracy. Detailed Photos

Size specification:

Product Parameters

| Machine type | Unit | TH-63S |

| Stroke | ||

| Table X-axis travel | mm | 1050 |

| Table Y-axis travel | mm | 750 |

| Table Z-axis travel | mm | 900 |

| Spindle | ||

| Spindle speed | rpm | 6000 |

| Spindle taper | - | 7/24 taper.50 |

| Spindle motor | kw | 15/18.5 |

| Worktable | ||

| Number of tables | 2 | |

| Table indexing | 1° /0.0010 | |

| Distance from spindle end to table center | mm | 130-1030 |

| Distance from spindle center to table surface | mm | 0-750 |

| Table area | mm | 630x630 |

| Maximum table load | kg | 1000 |

| Maximum swing diameter | mm | 950 |

| T-slot (number of slots x slot width x spacing) | mm | 5 x 22 x 125 |

| Displacement | ||

| X-axis rapid displacement | m/min | 24 |

| Ya-axis rapid displacement | m/min | 24 |

| Z-axis rapid displacement | m/min | 24 |

| Cutting feed speed | mm/min | 10-10000 |

| Tool magazine | ||

| Tool change type | type | Knife arm type |

| Tool shank type | type | BT-50 |

| Tool puller type | type | P-50 (45° ) |

| Tool magazine capacity (optional) | pcs. | 30T(40T/60T) |

| Max. tool diameter (no neighboring tool) | mm | 112 (200) |

| Max. tool length | mm | 350 |

| Max. tool weight (optional) | kg | 18 ( 25 ) |

| Others | ||

| Controller | OI-MF | |

| Floor space (L X W) | mm | 6600x4300 |

| Machine height | mm | 2900 |

| Machine weight | T | 14 (Floating difference 5% ) |

| Power requirement | KVA | 35 |

| Air pressure source | kg/cm2 | 6 |

Standard configuration:

Fanuc 01-MF machine

Automatic lubrication system

Ground bolts and spacers

Tool box

Working light

Three-color warning light

Electrical box heat exchanger

Transformer

Machine table air gun

Fully enclosed outer protection cover

chip conveyor and chip storage cart

Mobile hand wheel

Cooling pump

Robotic tool magazine

Hydraulic station

Foot switch

Optional Accessories:

10000/12000rpm direct knotted spindle

3-axis scale

Fifth axis rotary table

spindle center water outlet

Automatic tool length measuring system

Workpiece measuring system

Oil and water separation system

Oil mist collection and separation system

Mitsubishi/Siemens/Guandu/Kainty system

Automatic safety gate system

>> 24 Ton Wood Splitter / Cutter Machine 1200mm Ctm with New CE Wood Log Splitter

>> Ink Jet Printer for Pet Drinking Water Bottle Logo Printing Marking Engraving Numbers Coding

>> Wholesale Road Safety Aluminum Solar Road Stud

>> Dual Nozzle PA12 PC PP Professional 600*600*600mm 3D Printer

>> Shrink Packaging PTFE Threaded Pipe Gas Water Pipeline Seal Tapes for Plumbers

>> 175/70r13 185/70r14 195/65r15 Wholesale Factory Passenger Car Tyre

>> Piece Set of Dive Clothes Diving Clothing, Warm and Fishing, Hunting Hunting Clothing

>> Yiwu Market Road Shipping to Russia, Kazakhstan, Kyrgyzstan, Belarus, Mexico

>> Factory Xe265c Cheap Used Excavators Competitive Price

>> Paper Recycling Machine Tire Baler Machine Wast Plastic Bottle Baling Machine

>> Agricultural Equipment Farm Pasture Grass Cutting Rotary Disc Mower with Crusher

>> Custom Board Room Signs Finished in Brushed Metal

>> Factory Supply Wet Peanut Peeling Machine Peanut Red Skin Peeling Machine For red coat

>> Modern Design Fashion Designer Stylish Look Wholesale Genuine Leather Women Sling Bag at Competitive Price

>> Factory Directly Sale Psd Series High Speed Plate Drilling Machine

>> Hot Sale 7 Tiers Bakery Bread Trolley with Wheels

>> 5 Years Warranty 8 Heads Tubular Embroidery Machine

>> Super Bright Standard Bulbs Car Headlight H7 12V 55W Halogen Lamp

>> 10 in 1 Multifunctional Pliers Outdoor Hardware Factory

>> Factory Outlet Sale 25HP Small Scale Corn Harvester Single Row Corn Harvester

>> Air Blow Feed Grinding Grains Corn Grinder Machine with Syclone Collector

>> DTWMAC DTW-120A Woodworking Machinery Wood Sander with 3 Drum Rollers

>> Customized Polypropylene Sack Green Orange White Sand PP Woven Bag with String

>> Cleaning Sponge Hot-Press Design High Density Melamine Sponge By Optimus Direct Mfr

>> Sell Well Custom Logo Size Lightweight Printing Picnic Outdoor Picnic Camping Blanket

>> 25kg China PP Woven Block Bottom Packaging Fertilizer Sacks Bags

>> Sunswell Manufacture 24000bph Combiblock Blowing Filling Capping Machine for Carbonated Water

>> Laser Cutting Metal Electrical Aluminum Enclosure Steel Case

>> Collect Data Lora Wireless Communication Gateway

>> High Precision 5 Axis Machining Center Milling Machine for Metal Processing Vacuum Pump Rotors