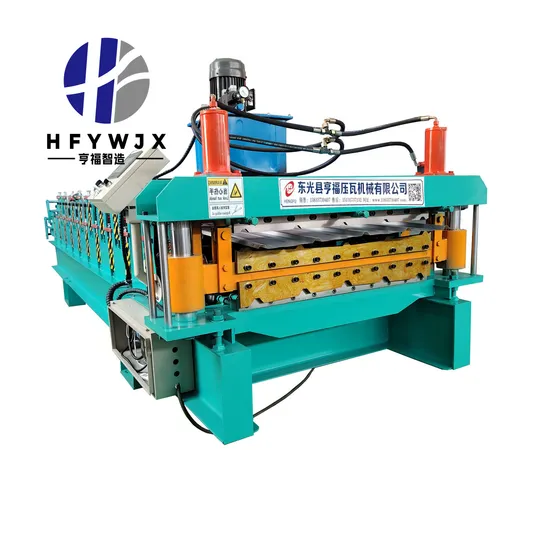

1000mm Double Layer Roll Forming Roof Wall Tile Making Machines Roof Roll Forming Machine

Basic Info.

Model NO.

Double layer roll forming machine

Tile Type

Colored Steel

Certification

SGS

Condition

New

Customized

Customized

Usage

Roof, Wall, Floor

Transmission Method

Hydraulic Pressure

Model

Double Layer Tile Press Machine

Transmission Mode

One Inch Chain

Cutting Method

Shear of Guide Column

Transport Package

Plastic Film & Steel Wire Fixed

Specification

6500mmx1300mmx1200mm

Origin

Dongguang, Cangzhou City

HS Code

8455221000

Production Capacity

400sets/ Year

Product Description

Basic Info.| Model NO | Double layer roll forming machine |

| Condition | New |

| Usage | Roof |

| External dimensions | 6500mmx1300mmx1200mm |

| machine frame | 300H steel frame |

| Number of rolling mill sets | 13-11 row molding |

| Roll material | 45 # steel rough lathe fine lathe outer circle grinding and electroplating treatment during addition |

| Spindle material | 45 steel |

| Spindle diameter | Φ70mm(Solid shaft) |

| Type of Driven | Chain drive |

| Forming Speed | 0-35M/min |

| Main motor power | 7.5KW |

| Electric control system | PLC |

| Customized | Customized |

| Origin | Cangzhou, Hebei |

| Warranty | 1 year |

Product Description

Double Layer Roll Forming Machine combines two models very well, with reasonable structure and beautiful appearance. It has the characteristics of saving space and simple operation, and is especially suitable for customers with small sites and on-site construction.

Double Layer Roll Forming Machine is mainly composed of a feed introduction platform, a forming host, a forming and shearing device, a hydraulic station, and a computer control system. The operation of switching between upper and lower floors is simple. You only need to use the conversion button on the electric control cabinet to control each floor separately. The power can also be controlled through the clutch to control each floor separately. Optional configurations include ordinary unloading machine and hydraulic unloading machine. The models of the upper and lower floors are determined according to customer requirements.

| Raw materials | Galvanized steel plate, color steel plate |

| Machine frame | 300H steel frame |

| Pull rod | 35mm galvanized |

Processing Flow:

Detailed Photos

1. Number of rolling mill units: 13-11 rows for forming

2. Roll material: 45 # steel rough lathe fine lathe outer circle grinding and electroplating treatment during addition

3. Spindle diameter: Φ 70mm

4. Spindle material: 45 steel

5. Cutting: Cut off after molding, guide column cutting

Company Profile

Hebei Hengfu Roll Forming Machine Co., Ltd. is a professional manufacturer of cold-bending forming equipment and its complete set of automated production lines. With advanced production equipment and product development and design capabilities, the products are at the leading level in the industry with the advantages of high rate, high precision, high flexibility, and low processing loss, and the products are favored by industry customers.

Our company's main products include: color steel plate equipment, glazed tile equipment, floor decking equipment, CIZ steel forming equipment, composite sandwich panel assembly line equipment, car compartment panels, dust removal anode plates and other equipment. We can design and manufacture special models according to user requirements, provide users with technical guidance, production installation, commissioning, and after-sales one-stop service.

In recent years, a large number of products have been sold to more than 50 countries and regions including Russia, India, the United Kingdom, Australia, Kazakhstan, etc., and have been well received by customers at home and abroad.

Certifications:

Company:

Workshop:

Customer & EXPO:

Transaction transportation:

FAQ

Q1: Are you a trading company or a factory?

A1: We are a manufacturer located in Cangzhou, Hebei. We have our own Having their own product design team. Welcome to visit our factory and inspect the quality of our machines on-site

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 12 months free warranty and free technical support for the whole life of any machine.If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5: Can you finish the machine during the delivery time?

A5: We will finish the machine in time according to determined lead time.

>> New Design 100% Rayon Dyed Fabric for Dresses Garment

>> High Speed Joint Leveling Machine

>> PE Series Jaw Crusher Equipment for Crushing Ores

>> Dream Diamond Lab Grown Hpht Diamond Cutting Machine

>> High Quality Billiard Table with 9FT Pool Table Size

>> Compost Turner Machine

>> Summer Joggerwholewholesale Custom Sports Muscle Bodybuilding Dry Fit Plain Tank Tops Gym Running Singlets Stringer

>> Multipurpose Oscillating Machine with CE for Wood Acrylic Foam Cardboard

>> Chinese Agriculture Rice Combine Harvester 688q Mini Rice Combine Harvester Paddy Beans Harvester Kubota Used 90% New Machinery

>> HC-S104 Full-featured nursing training simulator/ mannequin/training model

>> Awon Flail Mowers / Hedge Cutters for Sale

>> Japanese Tsukemono Pickled Radish Sakurazuke 0.75kg

>> Low Power Consumption Used Concrete Batching Equipment

>> Hot Sale Custom Logo Gym Equipment Fitness Accessories Plastic Coated Dumbbell

>> Insulation Resistance Spanish PVC Roof Tile Prices ASA UPVC Plastic Roofing Sheet for House

>> Car Parts Brake System Brake Rotor Disc Rear Brake Disc 1jo309617b for VW

>> 300*300mm 1/4 Fold Double Layer Napkin Paper Machine with 3 Colors Printing

>> High-Quality Pet Bottle Preform Injection Mold for Efficient Production

>> PCD230A 3BHE022291R0101 ABB Input and output device of excitation system

>> Frt3018 Giant Gantry Type Machining Center Heavy Duty CNC Gantry Milling Machine

>> Wholesale Butterfly Hand Engraving Party Home Table Decor Tea Coffee Cup Set

>> Automatic toothpick filling packing machine with paper film bag

>> Fine Bubble Aeration Membrane Tube Air Diffuser for Aquaculture Fish Farming

>> Gnvp Sheet Metal 1600X3200 V-Notching Machine for Sale

>> Centrifugal Oil Filter Machine

>> Speedy Ningbo to The Singapore Sea Shipping Solutions Spring Tube Shipping Logistics

>> V855 CNC Vertical Machining Center High Precision CNC Milling Machine CNC Machining Center Metal CNC Machine Tools

>> Jimbo Storage weapon fireproof gun safe box

>> Mango non latex free beauty egg powder puff Hydrophilicity beauty cosmetic blender mango shape makeup sponges

>> Outdoor Duty Knife Stainless Steel with Non-Slip G10 Handle For Camping Survival Knife