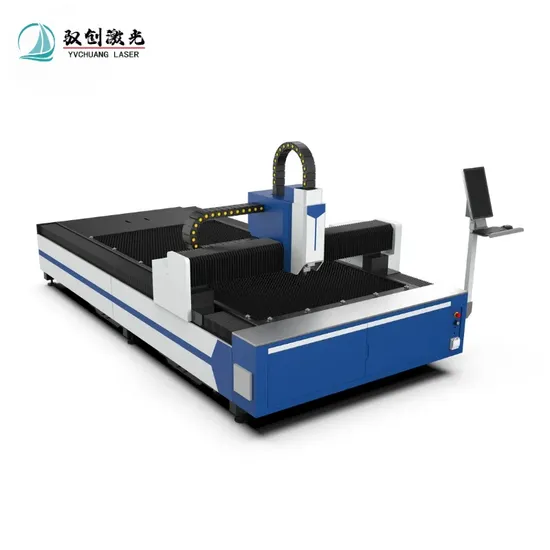

1000W 1500W 2500W CNC Metal Fiber Laser Cutting Machine Stainless Steel Aluminum Plates

Basic Info.

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Woodwork Industry, Advertising Industry

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Solid Laser

Laser Technology

Laser Control Fault Cutting

Model

Kf3015, Kf4020, Kf6015, Kf6020, Kf6025

Wavelength

1070nm

Sheet Cutting Area

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500

Laser Power

1000W / 1500W / 2000W / 3000W / 4000W / 6000W

X/Y-Axis Positioning Accuracy

0.03mm

X/Y-Axis Repositioning Accuracy

0.02mm

Max. Acceleration

1.5g

Max. Linkage Speed

140m/Min

Laser Head

Switzerland Raytools Auto Focus

Laser Source

Raycus / Max / Ipg

System

Cypcut

Weight

2500kg

Tube Cutting

Optional

Servo Motor

Inovance

Servo Driver

Inovance

Transport Package

Wooden Box

Specification

4*2.5*1.8m

Trademark

KNOPPO

Origin

China

HS Code

8456110090

Production Capacity

200 Sets/Month

Product Description

Product DescriptionThe robust and heavy-duty bed ensures unparalleled stability during operation, while the lightweight crossbeam enables faster and more efficient performance. The exquisite industrial design is meticulously crafted for optimal ergonomic interaction; the premium quality electrical software control system significantly enhances cutting precision. Enjoy a machine that offers supreme operational comfort, unrivaled stability, longevity, superior cutting efficiency, and an expansive range of applications.

Applicable Industry Of CNC Fiber Laser Cutting Machine for Sheet Metal Ideal for industries such as metalworking, advertising signage, interior and exterior decoration, fine arts, electronics, electrical appliances, agricultural machinery, metal spare parts production, furniture manufacturing, and window and door fabrication.

Applicable Materials Of CNC Fiber Laser Cutting Machine for Sheet Metal

Capable of cutting through a diverse array of materials including metal, carbon steel, stainless steel, iron, aluminum, brass, copper, mild steel, and galvanized steel tubing.

Product Parameters

| Model | KF3015 | |||

| Laser Power | 1000W/1500W/2000W/3000W/4000W/6000W/8000W/12KW/15KW/20KW / 30KW / 40KW | |||

| Working area | 3000*1500mm / 4000*2000mm / 6000*1500mm / 6000*2000mm / 6000*2500mm | |||

| Machine overall dimensions | 4550*2300*2000mm | |||

| Machine weight | 3000kg | |||

| Max. linkage speed | 140m/min | |||

| Max. acceleration | 1.5G | |||

| Positioning accuracy | 0.03mm | |||

| Repositioning accuracy | 0.02mm | |||

Detailed Photos

Premium Switzerland Raytools or Germany Precitec Laser Head

World-Renowned Switzerland Brand Ensures Excellence. Raytools stands as the global leader, celebrated for its superior quality. Advanced double water-cooling structures maintain optimal temperature control for collimating and focusing components, ensuring lens integrity and longevity. The protective lens acts as a safeguard for essential components.

High-Performance MAX Laser Source

As China's leading laser source producer, MAX epitomizes quality, capable of cutting through carbon steel, stainless steel, and aluminum. Known for its robustness and endurance, it is the ideal choice for continuous 24/7 operations.

Durable and Robust Welding Machine Body

Engineered for high compressive strength and toughness, it offers exceptional shock absorption and wear resistance. Its design minimizes thermal sensitivity and bed gap sensitivity, preserving machine precision over time, ensuring no deformation throughout its lifecycle.

Precision Japan YASKAWA Servo Motor

1. Utilizing Japan Yaskawa servo motor with a closed-loop control system guarantees precise positioning and optimal dynamic response during acceleration, ensuring smooth, reliable, and maintenance-free automatic positioning.

2. High-powered X, Y, Z axis motor drive with rapid acceleration reaching up to 1.5G.

Sophisticated Cypcut Control System

This intelligent operating system provides advanced graphic cutting layouts, supports multiple graphic imports, and automatically optimizes cutting sequences. It features smart edge detection and automatic positioning. The state-of-the-art logic programming and user-friendly software interaction offer an exceptional operational experience, maximizing sheet metal use and reducing waste efficiently. The system is designed for simplicity and speed, ensuring precise cutting commands and significantly enhancing user satisfaction.

Additional High-Quality Detail Photos

Innovative Water Chiller Efficient Automatic Lubrication Pump

Powerful Exhaust Fan Reliable Taiwan HIWIN Rails

Sturdy Blade Table Protective Cover for Cable Management

Sample

Customer Feedback

Certifications

Our state-of-the-art fiber laser cutting machine proudly carries the prestigious CE certification. Its design, electrical schematics, and quality meet and exceed the rigorous standards set by Europe, ensuring top-notch performance and safety.

After Sales Service

* Enjoy peace of mind with a comprehensive 3-year guarantee covering the entire machine, complemented by our pledge of lifetime maintenance, absolutely free.

*Immerse yourself in our free training sessions at our factory, ensuring you gain mastery over the operation of your machine.

* Benefit from our around-the-clock online support available through Whatsapp, Skype, Email, or a direct phone call.

*Our expert engineers are at your service, ready to provide overseas training and dedicated after-sale support.

* Navigate with ease using our user-friendly English manual and comprehensive operation video CD disk.

Company Profile

Knoppo Automation Pioneering the future of industrial laser technology, Knoppo Automation stands as a global leader in crafting state-of-the-art laser solutions. Our unwavering dedication to delivering intelligent laser equipment empowers businesses across the globe to boost efficiency and competitiveness. With an impressive legacy of over 15,000 laser cutting systems deployed worldwide, we are committed to expanding our global footprint rapidly. Knoppo Automation Strategically positioned to cater to a diverse international clientele, Knoppo Automation ensures unparalleled quality and swift response times across more than 100 countries. Our core ethos revolves around relentless innovation, perpetual enhancement, and the swift evolution of cutting-edge technologies. These efforts are meticulously directed at enhancing efficiency, optimizing flexibility, and reducing costs, all while championing sustainability and eco-friendliness for the betterment of all. We are devoted to delivering key technological advancements and bespoke integration solutions tailored for Industry 4.0 and smart factory environments, empowering enterprises to fully harness the boundless opportunities presented by the digital era.

Our diverse product portfolio encompasses not only sophisticated flat sheet cutting systems in an array of designs and dimensions, but also advanced laser tube cutting systems, CO2 laser cutting and engraving machines, laser marking machines, and more. Our dedicated and highly skilled R & D team, complemented by a meticulously trained, systematic after-sales technical department, ensures a truly customer-centric service experience.China Low Cost CNC Fiber Laser Cutting Machine High-speed 1530 Laser Cutter designed for precision cutting of metal, specifically stainless steel.

>> Multifunctional Screen Brush and Dust Brush Cleaner Foldable Detachable Window Mesh Screen Cleaner Brush with Wet and Dry Dual

>> Highly Springy Sponge Spring Mattress for Hotel

>> New Design Blow Molding Machine for Bottles

>> Free Sample Japanese Spam Musubi Roasted Seaweed Wholesale 100 Sheets Yaki Sushi Nori

>> Bicycle Parts 31.8mm Aluminum Alloy Fixed Gear BMX Bicycle Short Handlebar

>> Adjustable Pregnant Women Sleeping Pillow Cushion Pad Soft Pregnancy Side Sleepers Pillow

>> Marble/ Building Bricks Cutting Saw Machine

>> White Canvas Layflat Hose Pin Folded Fire Cabinet Fire Fighting Hose for Fire System

>> High-Performance Kl600s Concrete Vibrating Truss Screed for Professionals

>> Automatic water filling bottling and capping packaging machine production line

>> Grey Parcel Drop Box Foldable Parcel Box Drop Delivery Off Box

>> max working width 360mm to 1000mm Paper Cutting Machine automatic roll to sheet cutting machine paper sheeter machine

>> Electrical Educational Equipment for College Bridge Crane Semi-Physical Training & Assessment Equipment

>> JOHNCOO Soft Frog Lure Wholesale 3cm 5g Frog Baits With Spinner Top Water Fishing Lure

>> New Tengyang High Pallet Palletizer Robot Full-Automatic Tygw-500

>> Material Processing Copper Aluminum Brass Stainless Steel CNC Milling Robot Small CNC Mechanical Parts

>> M5t High Precision Vertical and Horizontal Milling Machine Turret Type Metal Universal Radial Milling Machine

>> Tpx3000 Rice Wheat Straw Rotary Cutter 6-8t/H Straw Bale Chopper

>> and Handrail, Fence Composite WPC Outdoor Deck Floor

>> China supplier stainless steel perforated mesh

>> Factory Direct Sales 47.1/36.6/29/28/24/21/19 Inch Long IPS LCD Display Module 3840*160 Resolution Display Panel

>> High Stainless Steel Bank Deposit Case Safe Vault Box Safe Vault Door

>> China Manufacturer Hongyuan Powder Coating Oven with Ss Steel Electric Heaters

>> WPC Green Material M+ Colors Wood Plastic Composite Solid Decklaminate Wood Floor Decorative Floor Tile with CE, SGS, Fcs

>> High Quality Semi Automatic Bottle Blowing Machine Bottle Blower

>> 500kg/H Recycling Machine/Pet Bottle Recycling Line

>> Black Plastic Fine Mist Sprayer with PP Cap, Black Cleanser Liquid Mist Sprayer Pump

>> Q35-12 Multi-Function Iron and Angle Channel Punching and Shearing Machine Factory Price

>> Full Automatic Whiskey Wine Bottle Filling Capping Labeling Machine Production Line

>> LED High Bay Light (LAE-4120)