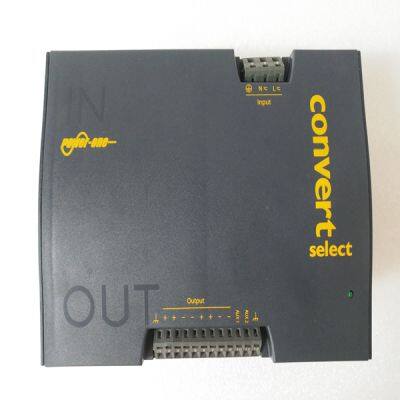

LXN1604-6

Product Details

Product Details

Product Description

Product DescriptionBrand:ABB

Type:LXN1604-6

Origin: the Swiss

Warranty: 365 days

Colour: new/used

Shipping method: Courier delivery

Module of PLC, DCS, ESD system card, the card is a vibration monitoring system, steam turbine control system module, the advantages of the gas generator spare parts brand: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, mechanical, electronic manufacturing, automobile manufacturing, plastic machinery, electric power, water conservancy, water treatment/environmental protection, boiler heating, energy, power transmission and distribution and so on.

EXTR/ADM Input Depending on the control action required, the Extr/Adm PID’s input signal can be inverted. When used with a typical extraction, admission or extraction/admission turbine application this input should not require inverting. Upon a loss of the Extr/Adm input signal during operation, the 505E can be programmed to trip, continue running and ramp the LP valve to its open limit, or continue running and ramp the LP valve to its closed limit. When a failed input is sensed the LP valve limiter steps to the LP valve’s last position, then ramps at a 1% per second rate to its min or max limit, depending on the programmed settings. The 505E senses an input failure and issues an alarm if the 4–20 mA Extr/Adm input signal goes below 2 mA or above 22 mA.

Extraction control can be automatically or manually enabled and performed after one of the 505E’s three starts have been accomplished, and related permissives met. Typically a turbine is controlling speed/load at a rated speed setting and loaded to a minimum load point before extraction control is enabled. After a startup, the HP and LP valve limiters should normally both be fully open. If the HP valve limiter is not fully opened, it will act as a speed/load limiter and will interfere with automatic governor operation. When configured for Extraction control the 505E’s LP valve limiter is high signal selected with the output of the Ratio/Limiter. Because the LP valve limiter is automatically ramped to 100% during system start-up the LP valve cannot be controlled below its 100% open position. All related Extraction enable permissives must be met before the 505E will allow the Extr/Adm PID to take control of a process.

The Extraction and/or Admission enable permissives are: • Extr/Adm input not failed • Turbine speed above programmed permissive speed • Gen breaker closed (if configured) • Tie breaker closed (if configured) There are two ways of enabling/disabling extraction control: manually or automatically. The manual enable/disable routine uses the LP valve limiter’s raise/lower commands, and automatic enable/disable routine uses an enable/disable command. Automatic enabling/ disabling can only be performed if the “Automatic Enable?” setting is programmed “Yes”. With automatic Extraction enabling programmed, an operator can also enable and disable Extraction control manually if desired. Manual Enable / Disable To manually enable Extraction control slowly lower the LP valve limiter until the Extr/Adm PID takes control of its process, then continue running the LP valve limiter to its minimum (closed) position. If the LP valve limiter is not fully closed, it will act as an extraction limiter and will interfere with automatic governor operation. All related Extraction permissives must be met before the 505E will allow the LP valve limiter to be lowered, and Extr/Adm control enabled.

>> Industry ED3-16mm Drill Grinder End Mill Sharpening Machine Tool Sharpener

>> Compression Travel Packing Cubes Set 7-Piece Lightweight Organizers for Suitcases

>> High Standard Mini Plansifter Low Priced Small Single Sifter Hot Product for Flour Mill

>> Wholesale Low MOQ Insulated Sports Bottle Stainless Steel Water Bottle

>> Jwell PE PP HDPE Film Plastic Crushing & Washing Machine

>> 036906051 036906051d 0369980411 Pressure Sensor for VW Bora Polo Skoda Fabia

>> Double Sided Leather Top Layer Cowhide Tote Bag Genuine Leather Women′s Bag Versatile Portable Shopping Totes Bags

>> Modern Glossy White Midnight Blue Bathroom Vanities Larch Canapa, Grey Walnut, Glossy White with LED Mirror Cabinet

>> High-Quality Construction Plywood for Building Projects

>> Walley Poultry/Meat/Dairy Products Mesh Belt/Plate Belt Tunnel Quick Freezer

>> Hot Selling Rechargeable COB LED Portable Work Light for Camping USB Rechargeable Mini COB Work Light Keychain LED Flashlight 80

>> Taijia Concrete Rebar Detector Locator Scanner ZBLR800 Integrated Rebar Locator Rebar Corrosion scanner

>> custom printed foil laminated mylar ziplock bags from china

>> STORM FAN 250*56mm 24/48V DC Industrial centrifugal fan plastic impeller

>> 2000BPH liquid rinsing filling and capping bottling machine for beverage water bottle production line

>> Drill Bit Grinder with High Precision Electric Motor and Sharpener

>> Fashion Accessories 5cm Nylon Fabric Crochet Lace Trimming

>> 9000BTU Acdc on Grid Inverter Solar Air Conditioner for Europe

>> PVC Customized Film Crystal Soft Sheet

>> Ruihang Saving Energy Plastic Crusher Crushing Machine

>> China Factory Blow Molding Machine Extrusion Blow Moulding Machine for Small Bottles

>> High Precision Full-Automatic Surface Cylinder Block Grinding Milling Machine for Cylinder Head Engine Long Service Life

>> New 2024 Byd M6 Rhd 3D TPE Car Floor Mat by Mipi

>> 2300 kN Plastic Infusion Set Making Injection Molding Machine

>> OE 83320-0k020 Flotante De Gasolina For Hilux Forunner Toyota Bomba Gasolina Completa OE 77020-0K080

>> Automatic Plastic Pillow Bag Sweet Chocolate Candy Bread Biscuit Flow Packing Machine Production Line

>> Decorate Your House with Plastic Zipper Doors

>> Solar Power Frequency Multifucntional Inverter

>> Office Stationery Custom Design Cover Offset Paper Promotional Items Memo Sticky Notepad

>> Primapress 70t 1600mm Sheet Metal CNC Hydraulic Mini Press Brake with Delem Da53t Controller