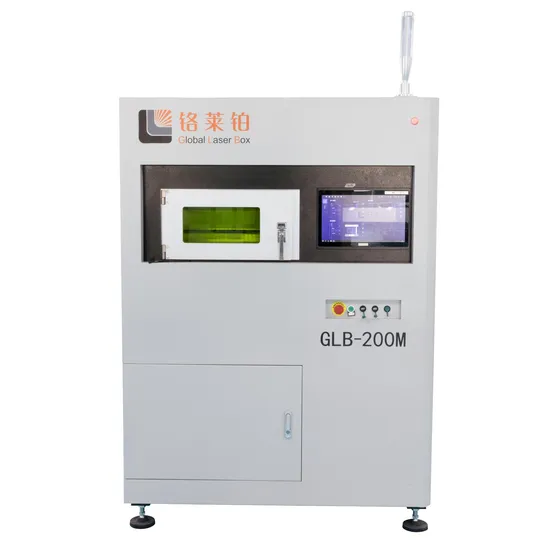

Slm 3D Printer Machine Industrial Provided High Performance Automatic Metal 3D Printer

| US$1.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

200M

Connection

USB

Precision

200-500mu

Thickness

20-80mu

Printer Material

Metal

Forming Technology

Slm

Operating System

Windows10

Print Size

φ150mm*90mm

Production

120 Crowns(6h)/11 Frameworks(8h)

Machine Weight

800kgs

Powder Layer Thickness

0.03mm-0.06mm

Scanning Speed

7-12m/S

Transport Package

Wooden Box Packaging

Specification

1280mm*810mm*1860mm

Trademark

Global Laser Box

Origin

China

Product Description

Product Description1. Big enclosed size: using integrated design, very easy to operate. 2. Simple operation: the software interface is friendly and easy to learn; integrated automatic centering function, the operator can easily place the crystal. 3. Strong adaptability: according to the movable requirements of the machine, the core components are equipped with a shock-proof system, which can effectively prevent damage to the core components of the machine due to accidental impact during equipment transportation and use. 4. Fast engraving speed: using galvanometer laser high-speed scanning working mode, the speed can reach up to 300,000 points/min, saving engraving time. 5. High stability and delicate engraving effect: using advanced air-cooled semiconductor end-pumped solid-state laser technology. 6. Adopt sealed integrated design, good beam quality, high stability, and delicate engraved dots. Can work stably for a long time. Product Parameters

| Equipment Size | 1280mm*810mm*1860mm |

| Print size | φ150mm*90mm |

| Production | 120 crowns(6h)/11 frameworks(8h) |

| Machine Weight | 800KGS |

| Powder Layer Thickness | 0.03mm-0.06mm |

| Powder Delivery Method | Bottom-feed Powder Delivery |

| Powder Spread Method | One-way Powder Spread |

| Scanning Speed | 7-12m/s |

| Control Software | Developed by GLOBAL LASER BOX (YM Build II ) |

| Data Processing Software | VoxelDance |

| Laser Brand | EVERFOTON |

| Scanning System | PSI High Precision Scanning System |

| Beam Diameter | 90-120μm |

| Laser Power | 500W×1 |

| Protective Gas | Nitrogen, Argon |

| Equipment Power | 3KW |

| Operating Environment | Temperature 25±3°C, Humidity <75% |

| Supported Print File Format | STL |

| Automatic Setup and Monitoring Alarm | Supported |

FAQ 1. What is the electrical configuration to install to power the machine, socket, power supply, electrical safety

• 120 M

Voltage 220V the socket can change local standards

• water cooling

Voltage 220V

• powder collector

Link the printer for power supply

2. Slicer software

• price

$1500/Year,$7000/Life time

• who does the maintenance

Software company

• Cost of maintenance and update

The fee includes maintenance and updates.

3. Information on chrome cobalt and titanium powders

• Heat treatment process for framework and coping/full unit and long bridge

Different powder have different heat treatment powder temperatures.

It is only related to the materials and has no relation to the printed products.

• Different granulometry offered

15-53μm

• Photo for marketing

• Packaging I must personalize

I do not recommend changing the manufacturer's name and logo

Because it involves a certificate.

4. Support disc chrome cobalt and titanium

• Thickness

20mm

• Fixing in the machine

Magnetic

• How many prints to recommend

Recommended printing times: over 200 times; grinding amount: remaining 8-9mm.

• How to surface after printing

Grinding bed, Hand Grinder

5. Photos and video of the technical parts of the machine

• Electrical compartment

• Laser compartment

• Filtration compartment

not available for now

6. Maintenance after photo and video printing

• Time for cleaning before reprinting

Cleaning time before reprinting: Clean the forming chamber for ten minutes.

• Annual maintenance

The permanent filter cartridge requires no maintenance and can print over 20,000 times.

• Cleaning the powder collector

Permanent filter element does not require cleaning.

• Water level of the water cooling

Add purified water above green.

7. Surveillance camera information

• Remote connection to PC and telephone

• Send a video so that I can check

8. Chrome printing times and quantity cobalt and titanium

• Framework

7-8

• Coping and full

80-90

9. how long is the training

• learn the slicer

• learn the machine software

• learn the machine start-up

• learn the post-processing

• learn the machine cleaning and collector

• learn the annual maintenance

About 3 days

>> ZXY High Quality Assurance Precision 6011-RZ/YA One Way Rodamiento Deep Groove Ball Bearing Original

>> Solar Thermoelectric Generator 5.77m Opening 12m Long Concentrating Parabolic Collector

>> Modern Design Bedroom Ceiling Decorative Louvers Panel

>> Factory Water Supply Coupling Elbow Cross Tee PVC Pipe Fitting Mold

>> High Quality PVA Mop with Two Rollers Stainless Steel Handle Soft Quick Dry PVA Mop

>> Soft Fleece Colorful Flannel Fleece Fabric for Blanket

>> High Quality 3/4" Gray Socket End Industrial PVC Swing Check Valves ANSI UPVC 3/4 Inch Water Pipe Check Valves Plastic Non Return (NRV) Swing Check Valves

>> Residential Exterior Double Glazing Aluminum Soundproof Aluminum Glass Patio Sliding Bifold Door

>> Mould Maker Plastic Injection Mold Moulding Machine Plastic Injection Molding with Metal Insert

>> Parts Engine Parts Genuine Gasket Cylinder Head Cylinder Head Gasket 2231125012 22311 25012 22311-25012 For Hyundai

>> Video Display Interactive Smart Electronic Electronic Writing Big Board

>> Floating Fish Feed Extrusion Machinery Special Double Screw Extruder Machinery

>> Stick Ice Cream Machine Robot Piuc up System for Linear Machine Large Capacity

>> 20411-T Metric Female 24° Cone with O-Ring Dko-L Metal Fitting

>> Xty Amusement Park Rides Motorcycle Electric Amusement Prince Motor Bike Ride

>> Al4000 Hot Selling Self Loading Concrete Mixer

>> Designers Famous Brand Amiri‘ S Luxury Jeans Straight Custom Trousers Skinny Jeans

>> Horizontal Double Shaft Paddle Mixing Machine Paddle Mixer for Powders and Granules Fertilizer/ Milk Powder/Protein/Vitamin Powder/ PVC/PE/ EVA

>> Madly PP Material Body Kit for BMW 5 Series F10 Style M5 body kit

>> Hertz Colorimetric Method 6 Cups Automatic Transformer Oil Acidity Tester

>> X/Y Axis Positioning Accuracy ± 0.03mm/M CNC Dual-Table Fiber Laser Cutting Machine

>> Heavy Duty Large CNC Horizontal Lathe Machine Tool Big Horizontal CNC Lathe with Low Price

>> Adult Big Long Hair Silicone Swimming Cap, High Elasticity Thick Swim Hats for Long Hair, Bathing Swimming Cap

>> High Technology F230 wireless crack width gauge

>> CNC Fast Speed EDM Drill Small Hole Machine

>> Solid Rubber Wheel Making/Wheelbarrow Solid Tire Making/ Rubber Powder Wheel Making Machine/Rubber Press

>> Dewo Yuanbao-Shape Sexy Bubble Plunge Soaking Hot Bathtub Rich Bubble Stomata Satisfying Imagination (EE645)

>> Vacuum Suck Single Facer Corrugated Machine with Stable Working Performance

>> Hot Sell Good Quality Circular Knitting Machine Spare Parts Electronic Yarn Storage Feeder

>> L Shaped Acrylic Menu Holder Stand Clear Menu Holder Stand Slanted Display Stand Custom Acrylic Sign Holder for Advertising