Large Tooling Nc Press Brake with CE Certificate

Basic Info.

Model NO.

wf67k-e

Condition

New

Certification

CE

Automation

Automatic

Suitable for

Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Type

Press Brake

Name

Metal Folding Machine Aluminum Sheet Bending Machi

Machine Type

CNC Press Brake

Keyword

Hydraulic Mechanical Servo CNC Press Brake

Control System

Da69t-Da66t-Da58t-CT8-CT12

Worktable Length

3200mm

CNC Control Axis

Y1-Y2-X1-X2-R1-R2-Z1-Z2

Voltage

220V/380V/415V/440V/Customized

Hydraulic System

X Y Axis Hydraulic CNC Press Brake Machine

Motor Band

Siemens Motor

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

Transport Package

Sea Worthy Packing. LCL in Wooden Case. FCL Fixed

Specification

customized

Trademark

Rongwin

Origin

China

HS Code

8462230000

Production Capacity

100 Sets/Month

Packaging & Delivery

Package Size

300.00cm * 200.00cm * 200.00cm

Package Gross Weight

1000.000kg

Product Description

Product Introduction| Large Tooling Nc Press Brake With Ce Certificate |

High precision and fast speed

The main cylinders on both sides are synchronously controlled by electro-hydraulic servo valves imported from Germany and German grating ruler closed-loop control. The feedback is accurate and the slider runs accurately, so that the bending accuracy ensures the repeatable positioning accuracy of the slider.

Function

Two machines can be linked, three machines can be linked, etc. to improve efficiency. Standard configuration

Product advantages

Features: High precision and fast speed

1.On both sides of the main cylinder synchronization use Germany imports of electro-hydraulic servo valve and the Germany grating closed-loop control, accurate feedback, the slider running accurately, thereby bending the accuracy slider repeat positioning accuracy.

2.Adopts steel plate welded structure, with tempering process and vibration aging treatment, Elimination the working stress and eliminating welding stress caused deformation, ensuring the precision of the machine tool maintenance.

3.The fuselage uses the split assembled structure, convenient transportation, convenient processing, can ensure the accuracy of the machine tool.

4.Equip with a sectional die, the workpiece can be assembled into a required length, to suit the special processing requirements of workpiece, punch using safety trench structure (European standard), mold structure very convenient to disassembly and assembly.

5.Standard with DELEM DA69T CNC controller system.(Interchangeable system)

6.Rexroth of Germany's high-performance servo-hydraulic control system synchronization.

7.Italy grating rule simultaneous detection of position feedback encoder with both side.

8.Back gauge with high-performance servo motor and ball screw . ! automatic crowning compensation with CNC system. 9.Standard with a set of CNC press brake mould. Part upper-die is be readied, assemble to the length of needing work piece as to adapt to particular processing work piece

10.The mechanism of back stopper with multiple stopping shafts for complete functions is employed. The function work piece, as guide way, lead screw, bear etc. are imported to ensure the stopping precision of back stopper.

11. C-shaped plates are fitted on both sides of the machine body, and the high-precision grating ruler is mounted on the C-shaped plates, thus to avoid the influence over bending precision arising from distortion of machine body during bending process.

12.Oil cylinder from special manufacture and industry, seal rings imported from Germany, and pipe connections imported from EMB Germany.

Optional configuration

Crowning Table Workbench adopts mechanical torsion compensation system , as the mechanical compensation point , so the mechanical compensation effect is far greater than the hydraulic compensation , to achieve effective compensation without blind spots and improve the bending accuracy , to ensure the long-term stability.

Packaging & Shipping

Technical parameter

| Model | Nominal Pressure (mm) | Workbench length (mm) | Poles distance (mm) | Throat depth (mm) | Slipper Stroke (mm) | MaxOpen (mm) | Main motor (KW) | Dimension (L×W×H)(mm) |

| 30T/1600 | 300 | 1600 | 1250 | 170 | 90 | 195 | 3 | 1600×920×1660 |

| 30T/2050 | 300 | 2050 | 1450 | 170 | 90 | 195 | 3 | 2050×920×1660 |

| 40T/2200 | 400 | 2200 | 1850 | 245 | 100 | 330 | 5.5 | 2260×1200×1950 |

| 40T/2500 | 400 | 2500 | 2150 | 245 | 100 | 330 | 5.5 | 2560×1200×1950 |

| 50T/2500 | 500 | 2500 | 2150 | 245 | 100 | 330 | 5.5 | 2560×1200×1950 |

| 63T/2500 | 630 | 2500 | 2000 | 250 | 120 | 350 | 5.5 | 2560×1350×2120 |

| 80T/2500 | 800 | 2500 | 2000 | 250 | 120 | 350 | 7.5 | 2560×1350×2120 |

| 80T/3200 | 800 | 3200 | 2580 | 250 | 120 | 350 | 7.5 | 3260×1350×2120 |

| 80T/4000 | 800 | 4000 | 2980 | 250 | 120 | 350 | 7.5 | 4060×1350×2250 |

| 100T/2500 | 1000 | 2500 | 2000 | 300 | 130 | 400 | 7.5 | 2560×1465×2300 |

| 100T/3200 | 1000 | 3200 | 2580 | 300 | 130 | 400 | 7.5 | 3260×1465×2300 |

| 100T/4000 | 1000 | 4000 | 2980 | 300 | 130 | 400 | 7.5 | 4060×1465×2300 |

| 125T/2500 | 1250 | 2500 | 2000 | 300 | 130 | 400 | 11 | 2560×1465×2350 |

| 125T/3200 | 1250 | 3200 | 2580 | 300 | 130 | 400 | 11 | 3260×1465×2350 |

| 125T/4000 | 1250 | 4000 | 2980 | 300 | 130 | 400 | 11 | 4060×1465×2350 |

| 160T/3200 | 1600 | 3200 | 2580 | 340 | 150 | 450 | 11 | 3260×1620×2700 |

| 160T/4000 | 1600 | 4000 | 2980 | 340 | 150 | 450 | 11 | 4060×1620×2700 |

| 160T/5000 | 1600 | 5000 | 4000 | 340 | 150 | 450 | 11 | 5060×1620×2850 |

| 160T/6000 | 1600 | 6000 | 5000 | 340 | 150 | 450 | 11 | 6060×1620×3000 |

| 200T/3200 | 2000 | 3200 | 2580 | 340 | 150 | 450 | 15 | 3260×1620×2700 |

| 200T/4000 | 2000 | 4000 | 2980 | 340 | 150 | 450 | 15 | 4060×1620×2850 |

| 200T/5000 | 2000 | 5000 | 4000 | 340 | 150 | 450 | 15 | 5060×1620×2850 |

| 200T/6000 | 2000 | 6000 | 5000 | 340 | 150 | 450 | 15 | 6060×1620×3000 |

| 250T/3200 | 2500 | 3200 | 2580 | 400 | 200 | 500 | 18.5 | 3260×1700×2900 |

| 250T/4000 | 2500 | 4000 | 2980 | 400 | 200 | 500 | 18.5 | 4060×1700×2900 |

| 250T/5000 | 2500 | 5000 | 4000 | 400 | 200 | 500 | 18.5 | 5060×1700×3000 |

| 250T/6000 | 2500 | 6000 | 5000 | 400 | 200 | 500 | 18.5 | 6060×1800×3200 |

| 300T/3200 | 3000 | 3200 | 2580 | 400 | 200 | 520 | 22 | 3260×2000×3000 |

| 300T/4000 | 3000 | 4000 | 2980 | 400 | 200 | 520 | 22 | 4060×2000×3000 |

| 300T/5000 | 3000 | 5000 | 4000 | 400 | 200 | 520 | 22 | 5060×2000×3200 |

| 300T/6000 | 3000 | 6000 | 5000 | 400 | 200 | 520 | 22 | 6060×2100×3400 |

| 350T/3200 | 3500 | 3200 | 2580 | 400 | 250 | 570 | 22 | 3260×2000×3000 |

| 350T/4000 | 3000 | 4000 | 2980 | 400 | 250 | 570 | 22 | 4060×2000×3000 |

| 350T/5000 | 3000 | 5000 | 4000 | 400 | 250 | 570 | 22 | 5060×2000×3200 |

| 350T/6000 | 3000 | 6000 | 5000 | 400 | 250 | 570 | 22 | 6060×2100×3400 |

| 400T/3200 | 4000 | 3200 | 2580 | 400 | 250 | 580 | 22 | 3260×2000×3100 |

| 400T/4000 | 4000 | 4000 | 2980 | 400 | 250 | 580 | 22 | 4060×2100×2900 |

| 400T/5000 | 4000 | 5000 | 4000 | 400 | 250 | 580 | 22 | 5060×2000×3300 |

| 500T/4000 | 5000 | 4000 | 2980 | 500 | 300 | 640 | 37 | 4100×2300×3600 |

| 500T/5000 | 5000 | 5000 | 4000 | 500 | 300 | 640 | 37 | 5100×2450×4000 |

| 500T/6000 | 5000 | 6000 | 5000 | 500 | 300 | 640 | 37 | 6100×2450×4200 |

| 600T/4000 | 6000 | 4000 | 2980 | 500 | 300 | 660 | 45 | 4100×2300×3600 |

| 600T/5000 | 6000 | 5000 | 4000 | 500 | 300 | 660 | 45 | 5100×2450×4000 |

| 600T/6000 | 6000 | 6000 | 5000 | 500 | 300 | 660 | 45 | 6100×2450×4200 |

Company Profile

Founded in 2017 years ,Nanjing RONGWIN Machinery Technology Co., Ltd is focus on press brake manufacturing and a professional one-stop smart custom metal solution service supplier . We are committed to building a strong Chinese metal working machinery and spare parts supply Chain System .

We have a dream "Let China's one-stop smart custom metal solution serve the world " and "We want to become a respected Chinese press brake manufacture,live 100 years " That's why we're always trying to keep our users satisfied .

We are specialized at metal working machinery and spar parts, like press brake, panel bender,fiber laser cutting machine, shearing machine, rolling machine, V grooving machine, hydraulic press, power press, ironworker, notching machine, tube cutting machine,tube bending machine ,HVAC Dust Machine, punching die, blades, kinds of toolings, etc. We can give customer all the aspect solutions for the metal industry fabrication machinery. We can guide customers for choosing their metal processing equipment so that customer can get the most cost-effective solution by our guide. Meanwhile we also can do O E M & O D M service. We have professional engineer support, high efficiency sales team and competitive price , we design our machine in a top class level which makes our machine in a good looking appearance , due to the good after sale service and reliable quality, we have sold to many foreign customers, they like our machines, they usually buy from us not only one time, now we already sold to more than 70 countries, including Europe, South America like Brazil, U S A, Canada, Russia, Vietnam, Pakistan, Australia ,New Zealand, Africa, Middle East country etc. After several years' development, We already applied some patent, and also got CE certificate and SGS for Press Brake, Laser Cutting machine,Panel Bender,V grooving machine etc, we will grow up together with our customer's support, we believe that our company will have a bright future.

Please trust ROGNWIN .We are always trying to make you satisfied .

FAQ

Q1: Can you give us a better price?

A: The more products you buy, the more discounts you get.

Q2: Can I make a OEM order?

A: We can supply different sizes.our products can be customized.But you need to tell us more detailed requirements.

Q3: How does your factory do regarding quality control?

A: "Quality is priority." Our team always attach great importance to quality controlling from the very beginning to the verv end.

Q4: What's your MOQ order?

A: Usually it's a minimum order. If you need more, we can negotiate a discount.

Q5: How to find the right product?

A: You can provide us with photos or your requirements, and we can give you Suggestions as appropriate

>> Children′s Cute Cartoon Toy Photography Video Digital Instant Printing Camera

>> Mini DC UPS Power Backup Supply 12V Mini UPS for WiFi Router Security Camera

>> Electric Kebab Skewer Maker with High Efficiency

>> New Ultra-Thin Bluetooth Mini Wireless Mouse Silent Mute Crystal Transparent Wireless Rechargeable 2.4G Optical Wireless RGB LED Mouse

>> Custom PU Leather Journal Study Notebook Cover A5 Binding Business Notebook

>> persian pistachio pistache phistachios pistazien production of pistachio paste

>> Colorful Pyrex Glass Oil Burner Skull Design Glass Tobacco Pipes

>> stainless steel sintered metal wire mesh filter cartridge filter disc

>> High Quality Modern Design Steel Stainless Locker with Factory Direct Price Steel Storage Locker Wardrobe Locker Metal Steel Locker School Locker Gym Locker

>> Fertilizer Chain Animal Manure Crushing Machine Pulverizer Machine Price

>> Elite Factory Price Horizontal Pet Preform Injection Molding Machine

>> Industrial Factory Warehouse IP65 Waterproof 100W 150W 200W UFO LED High Bay Light

>> 2cm Concrete Beige Outdoor Walkway Tiles

>> Fuja 2 Heads Computerized Embroidery Machine 15 Needles

>> Best 2500 Square Meters/H Mechanical Sweet Corn Harvester for Sale

>> BRAND NEW REPLACEMENT X3 F25 RUBBER MOUNTING BRACKET FOR RADIATOR

>> China Wet Poultry Fish Feed Pellet Granulating Granulator Machine

>> Bed Type Drilling Milling Machine XZ5150 XZ5150A

>> Joston Emulsification Gelatin Melting Glue Mixer Tank

>> Manufactured Umbrella Head Roofing Nails with Factory Price

>> 201 304 stainless steel work table for kitchen equipment

>> 3.1 Channel Home Theatre System Hi-Fi DVD Multimedia Karaoke Speaker Big Music

>> Copper Cable Small Industrial Foam Shredder Machine for Sale Best Small Garden Shredder Biomass Straw Shredder Factory

>> Sterile Blender 110V/220V New Design High Quality Lab Flapping Homogenizer Touch Screen Aseptic Homogenizer

>> Waterjet Head Intensifier Spares 87K Low Pressure Cylinder (019975-1) (011290-1)

>> Tianhe Vh-300 Type Pharmaceutical Milk Food Dry Powder Mixing Machine Powder Mixer

>> New Radiator for BMW 3 Series F35 F30 330iX 340i 340iX F31 F34 17118625430

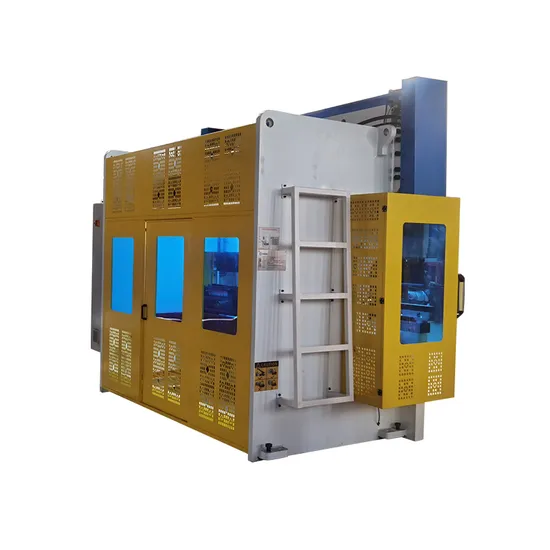

>> Car Spray Booth Paint Spraying and Drying Booth

>> Zy 705 Stainless Steel Tube Making Machine Welded Pipe Forming Tube Mill Machine

>> Wood Shaving Machine for Horse Chicken Animal Bedding