3.2 Two Component Moisture Curing PU Polyurethane Adhesive for Sandwich Panel

| US$1.50-2.50 | 20 kg (MOQ) |

Basic Info.

Model NO.

DF251

Application

Construction, Building, Industry

Material

Polyurethane

Classification

Room Curing

Main Agent Composition

Natural Polymer

Characteristic

Weatherability

Promoter Composition

Curing Agent

Composition

Polymer

Color

Yellow

Appearance

Yellowish-Brown Viscous Liquid

Viscosity (25ºC,)

1500----5000 Mpas

Active Period (Min)

10----90

Initial Curing Time (Min)

30----120

Packaging

10/25/250kg/Barrel

Transport Package

Drums, IBC Drums, Tanks

Specification

pure

Trademark

G-TECH@

Origin

China

Production Capacity

20000mt/Year

Packaging & Delivery

Package Size

23.50cm * 23.50cm * 37.50cm

Package Gross Weight

21.500kg

Product Description

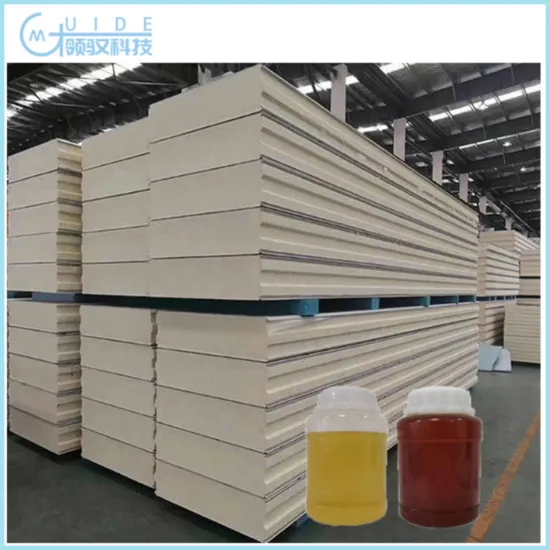

Product OverviewDF251 Two-component Polyurethane Adhesive is internationally recognized as one of the environment-friendly adhesives, whose formula is solvent-free and odor-free.

Application

Used for binding foam plastic, aluminum honeycomb, paper honeycomb, etc. and metal materials (for instance, iron, aluminum, stainless steel); also can be used for arbitrarily cross-binding among concrete, wood, hard PVC plastic, rubber and plastic, ceramics, rigid foam materials, thermal insulation plate , and various composite plates, etc.

Product Features

High solid content, less consumption;

Stronger initial adhesion, higher curing speed;

Bonding firmly; better quality of composite board products;

Better adaptability to material, speed, temperature, ratio of two components;

Highly cost effective, save cost for customers.

Technical Parameters

| Item | Component A (white adhesive) | Component B (black adhesive) |

| Appearance | Light yellow to yellow viscous homogenous liquid | Dark brown viscous homogenous liquid |

| Viscosity mpa.s(25ºC) | 300~500 | 300~500 |

| Bonding Strength(Mpa) | >0.1 | |

| Bond Area | ≥95% | |

| Ratio | 1:1 | |

| Production of board / pair | 6000m-11000m | |

| Parameter of foaming and gelling | Can produce according to customer's requirements and seasons and temperatures | |

-------------------------------------------Independent Report by SGS-------------------------------------

>> 120VAC to 12VDC 24VDC Class 2 Magnetic DC Drivers

>> High Precision Nantong Milling Machine with High Quality (X6325)

>> Cw6163 Cw6180 China Horizontal Metal Manual Turning Universal Engine Lathe Machine

>> Vertical High Speed Heating Mixer Cooler for Batch Mixing Blending of Thermoplastic Polymer Compounds

>> FM Transmitter Rainbow LED Car Radio Bluetooth Charger Car MP3 Player

>> Compact Euro Style Electric Hoist Steel Structure Industrial Single Beam Bridge Crane Lifting 10 Ton Overhead Crane for Sale

>> Agricultural Machinery Tractor Tiller Cultivator Pto Mini Rotary Power Tiller Hoting Selling Farm Implements 1gqn Series Rotary Tiller for Tractor Usage

>> Epsivo Hai Tian Injection Molding Machine Servo Motor Driver Controller 30kw

>> F17 Formply 1200*1800 for construction made in China

>> LED Acrylic Sign Making Channel Letter Bending Machinery

>> Sand Cone Density Apparatus Set for sale

>> Fanuc 6 Axis 2230mm Wingspan Automatic Robotic Arm Industrial Robot Arm with 80kg Load

>> Dw50CNC Pipe Bender Machine Chinese Factory

>> High Speed New Automatic Paper Folding Machine Industrial Grade Paper Folding Cutting Packing

>> Diesel Engine Wood Chipper for Wood Chips

>> High Quality Model AC Contactor Cjx2 Single Phase 220V Three Phase 380

>> Outdoor Waterproof & Sandproof Picnic / Beach Blanket/Mat/Rugs Blanket

>> Turret Slitter Rewinder Machine for Flexible Package Plastic Film, Laminating Film, BOPP Film

>> Cwap-1 2024 Best Quality Hospital Medical Furniture ICU Patient Bed Hospital Bed Accessories Electric Bubble Air Mattress with Air Pump AC110V/220V

>> MAICTOP Car body parts rear lower tailgate door for land cruiser 200 lc200 fj200 2008-2019 tail gate

>> Complete milk processing line and dairy factory equipment

>> Clip 3 Clip 4 Flip 6 Flip 5 Pulse 5 Pulse 4 Booms Box 3 Portable Bluetooth Wireless Speaker Box

>> Linen Polyester Sofa Fabrics Plain Linen Fabric Upholstery Sofa Polyester Linen Fabric

>> Timing Chain Kit Automotive Timing Tensioner TN1502 for VW;for SKODA;for AUDI;for SEAT CCTA/CCTB/CBFA with oe no.06K109467K

>> Premium Aluminum Amplifier Housing for Custom Metal Fabrication

>> Three Side Steel Structure Advertising Unipolar Billboard

>> Precision Servo Planetary Gearbox Ab Series Planetary Gearbox

>> High Quality Usa Big Polypropylene Kraft Paper Packaging System 5kg 30kg 35kg Sack Bag Charcoal Bags 25kg

>> IDQ helium gas used to inflate the helium balloons decorated for the wedding/festival /New Year/Christmas/Children′s Day/birthday

>> 2024 New Design Fashion Waterproof Unisex Chest Bag