Demark Low Calories Coco Sparkling Blowing Filling Capping Machine

| US$200,000.00-1,000,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

DMK-G5R12-72-72-15

Warranty

1 Year

After-sales Service

Engineers Fly to Clients′ Factory

Rated Capacity

36000 Bph

Bottle Volume

0.2 L- 2 L

Bottle Type

Round or Square

Cap Type

PE Screw Cap, Crown Cap, etc.

Transport Package

Wooden Case

Specification

Stainless Steel

Trademark

DEMARK

Origin

Huzhou, China

Production Capacity

18000 Bp/H- 60000 Bp/H

Packaging & Delivery

Package Size

723.00cm * 530.00cm * 280.00cm

Package Gross Weight

16000.000kg

Product Description

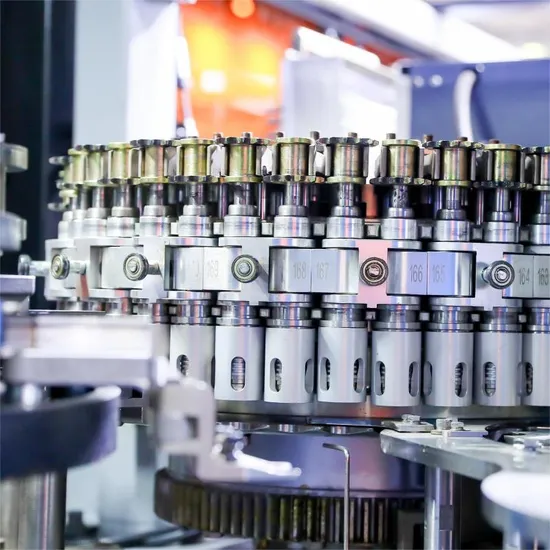

Demark Bottled Coco Sparkling Blowing Filling Capping CombiblockGeneral Description

The Demark Low Calories Coco Sparkling Blowing Filling Capping Machine is the ultimate solution for businesses seeking to streamline their production processes. This combiblock machine integrates three essential functions into one compact unit, eliminating the need for multiple machines and reducing the overall footprint in your facility. By combining the blowing, filling, and capping processes, this machine ensures a smooth and uninterrupted production flow, maximizing productivity and minimizing downtime.

This state-of-the-art machinery is specifically engineered for the production of soda water, offering a seamless combination of blowing, filling, and capping processes. With its exceptional performance and efficiency, this machine is set to revolutionize the soft drink filling machinery market. Working Process

With its advanced technology, the Demark Low Calories Coco Sparkling Blowing Filling Capping Machine guarantees high-quality results.

1. Blowing Unit The bottle blower component utilizes state-of-the-art technology to produce bottles with exceptional clarity and consistency. This ensures that your soda water products are presented in an appealing and professional manner, enhancing your brand image and attracting customers.

2. Filling Unit

The filling process of this machine is designed to maintain the integrity and quality of your soda water. It features precise filling mechanisms that accurately measure and dispense the desired amount of liquid, ensuring consistency in every bottle. This not only enhances the taste and experience for consumers but also reduces waste and improves cost-efficiency for your business.

3. Capping Unit

The capping function ensures a secure and leak-proof seal for each bottle. This guarantees the freshness and carbonation of your soda water, preserving its quality throughout its shelf life. With its reliable capping mechanism, you can be confident that your products will reach consumers in perfect condition, enhancing customer satisfaction and loyalty.

Technical Parameters

| ITEM | UNIT | DMK - G5R12-72-72-15 |

| Blowing Cavity | 12 | |

| Rinsing Head | 72 | |

| Filling head | 72 | |

| Capping head | 15 | |

| Productivity | bottle/h | 24000 |

| Volume | L | 0.2-2 |

| Material | PET | |

| Diameter of bottle | mm | 50-105 |

| Height of bottle | mm | 150-310 |

| Power | 380V50Hz | |

| Installation power | KW | 8 |

| Dimension of main machine | mm | 7230×5300×2800 |

| Weight | KG | 16000 |

Technical Features

The blowing filling capping combiblock is a game-changing technology that is set to revolutionize the bottling industry. With its innovative design, advanced features, and numerous benefits, it is the perfect solution for any beverage manufacturer looking to improve efficiency, reduce costs, and enhance product quality.

1. Reliable and efficient design. It is designed to handle the filling process with utmost accuracy and efficiency. Equipped with advanced sensors and controls, this machinery ensures precise filling levels, minimizing product waste and maximizing production output. The result is a reliable and durable packaging solution that maintains the integrity and freshness of your carbonated beverages.

2. Ease of use. The machine boasts a user-friendly interface, allowing operators to easily navigate and control the various functions. Its intuitive control panel provides real-time monitoring and adjustment options, ensuring seamless operation and minimizing downtime.

3. Highly flexible and versatile. It can accommodate a wide range of bottle sizes and shapes, allowing manufacturers to cater to diverse consumer preferences. This flexibility enables businesses to expand their product offerings and capitalize on emerging market trends.

4. Easily integrated with existing production lines, making it a cost-effective option for upgrading or expanding existing facilities.

5. Highest standards of quality and durability. Constructed with food-grade materials and incorporating advanced sanitization systems, it guarantees the production of contaminant-free and safe beverages. This not only ensures consumer satisfaction but also helps beverage manufacturers comply with stringent industry regulations.

In conclusion, the Demark Low Calories Coco Sparkling Blowing Filling Capping Machine is a game-changer in the soft drink filling machinery market. Its innovative design, seamless integration of processes, and advanced technology make it the ideal choice for businesses seeking to optimize their production processes and deliver high-quality soda water products. Invest in this machine today and experience the benefits of increased productivity, improved product quality, and enhanced customer satisfaction.

Company Profile

>> Seeyes Tractor with a Diesel Engine Ta304 Series Wheeled Tractor Ta304-A9

>> Balloons Water Summer Fun Reusable Silicone Water Balloons

>> 300ton Sanitary Fitting/ Bathroom Fitting / Sanitaryware Injection Molding Machine Stable Performance High Quality Competitive Cost Save Energy

>> Wholesale Diamond Drilling Bit Tools Manufacturer

>> Label Counting Rewinding Machine for Copper Foil, Aluminum Foil, Pet, PC, PVC, PCB, FPC, Battery Membrane, Flannelette, Material in Roll

>> China Unique Compact Xk-450X1200 Two Roll Mill

>> Trunking Light Recessed LED Aluminum Profile Cabinet LED Linear Light

>> 3.2cm Hunter Chocolate Rose-Red/Green Bright-Cyan Satin Ribbon for Bows Decoration/Toys/Festival/Gift/Wrapping/Packing-071045

>> Yuyun Sanhe Poultry Equipment Hanging Double Safenet Ventilation Exhaust Fan Ceiling Mount Animal Husbandry Livestock Machinery

>> Mars-GM2513 Automatic Stone CNC Router Countertops Cutting Machine Manufacturer

>> T3 Series Industrial Pipe Type Ultrasonic Flowmeter Sandwitch Type Ultrasonic Water Meters IP68

>> USA Market Residential Patio Thermal Break Aluminum Sliding Door with Blinds

>> Continuously Ultrasonic Cosmetic Processor Homogenizer Disrupter

>> Wood Treatment Preservation Equipment Wood Timber Vacuum Impregnation Autoclave

>> Unisex Custom Color Logo Size Polyester Knit Duck Tongue Cap

>> Hydraulic Wall Saw Concrete Wall Saw Cutting Machine Electric Wall Panel Saw Hydraulic Wall Saw

>> Heavy Duty Large CNC Controlled High Speed Gntry Drilling Machine

>> Cold Cutting Bag Making Machine with Four Servo Motors

>> Best Selling Custom Silent Rechargeable Bt Bluetooth 2.4G Wireless Mouse Mute Computer Wireless Optical Mouse Cordless Mouse with USB Receiver

>> Her303 Her305 Her308 Do-27 High Efficiency Rectifier Diode

>> Innovative High Speed Honeycomb Paperboard Production Line for Competitive Edge

>> Paper Coffee Cup Lid Cover Thermoforming Plastic Fruits Clamshell Packages Box Tray Forming Making Machine

>> 2024 Custom Logo Outdoor Portable 1L Thermos Flask Travel Vacuum Flask 1000ml Camping Water Bottle

>> Customized Sapphire Blades

>> Elastic Tension Band Swimming Arm Strength Trainer, Swim Paddle Fins Freestyle Swimming Training Aids Resistance High-Strength Exercise Band Esg13319

>> High Rigidity Gantry Structure 5 Axis Vertical CNC Machining Center CBS650

>> 2-PC Billiard Pool Cue Stick Holder

>> High efficiency big wheat thresher price rice sorghum threshing machine

>> Hot Sale Concrete Batching Plant, Ready in Stock with Good Price, China Supplier Direct Sale with Good Quality

>> Woven Wire Mesh for Window Door Porch Patio Sliding Door Screening