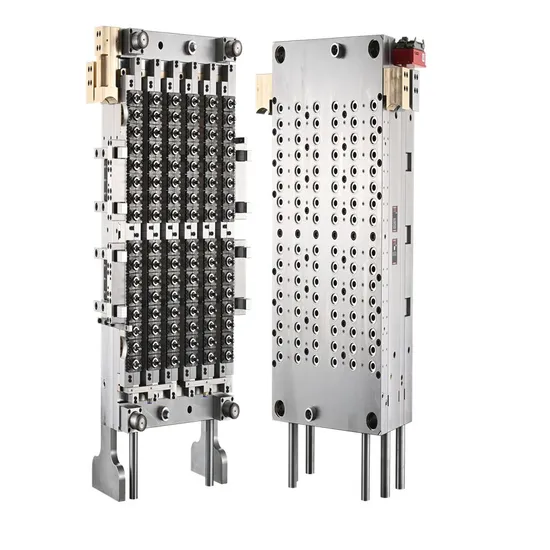

96 Cavity Pet Preform Mold Water Bottle Injection Mould

| US$1,800.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

preform mold 96

Surface Finish Process

Heat Treatment

Mould Cavity

Multi Cavity

Plastic Material

PET

Process Combination Type

Compound Die

Application

Plastic Package

Runner

Hot Runner

Design Software

AutoCAD

Installation

Fixed

Certification

CE

Standard

DME

Customized

Customized

After-sales Service

1 Year

Steel

Germany 2316 with HRC 42-45

Package

Woden Box

Transport Package

Export Standard Wooden Box

Specification

32 cavity

Trademark

DAELONG

Origin

China

HS Code

8480719090

Production Capacity

200 Set / Year

Product Description

Taizhou Huangyan Daelong Mold Co., Ltd ( Taizhou Huangyan Hengyuan Mold & Plastic factory) early from the establishment, is devoted to all kinds of Preform mould, Cap mould and other kinds of plastic mould.We continually works on development and improvement for holding the management tenets of integrity, Quality first and Credit Tops. By far, We are in possession of one lot advanced equipment and one excellent team. Our Products have already been setup good relationship with many domestic and oversea clients, We serve for customers with advanced technology, good quality, reasonable price and considerate after sale service, Our products are famous and get good reputation in both domestic market and oversea market.

| THE MATERIAL OF THE MOLD | |

| Mould cavity | Germany 2316 with HRC 42-45 |

| Mould core | Germany 2316 with HRC 45-48 |

| Mould neck | Germany 2316 with HRC 45-50 |

| Valve Pin | SKD51 from Japan with HRC 58-60 |

| Valve Pin heat Isolation pad | America Dupont can withstand 350 degrees temperature |

| Hot runner nozzle | America Beryllium copper with HRC 37 |

| Mould manifold plate | H13 from America with HRC 35-38 |

| Mould other plate | P20 |

| Other Specification of the Mould | |

| Hot runner system | Hot runner system is made by our own factory, But the spare parts of the Hot runner is from Germany Hotest |

| PID controller | Made by our own factory |

| Guarantee for the Mould | 1 million shot times of 1 year |

| Free spare parts of the mould | Core set : 1set/ cavity: 1 Piece/ hot runner system: 1set/PID controller system: 1Set/ other easy broken spare parts for each 8cavities cap mould. |

| The life of the mould | 5-6years , Even in 10 years in good maintenance |

| Installation & Commission | Our technician can be the buyer' s factory to install and run the mould. But the buyer should bear all the cost for the technician' s trip(include the air ticket, the cost of the accommodation and the salary) |

>> 3D Laser Marking Machine High-Precision Three-Dimension Positioning Technology

>> Bd-1300 Dredging Cutter Head for Cutter Suction Dredger with Pump Station

>> High Speed V Type Pharmaceutic Mixer/ V Shape Powder Mixer/ V Blender

>> Plastic Agglomerator/Densifier/Fiber Agglomerator

>> High Speed Fiber Laser Pipe Cutting Machine for Tube Metal Cutting

>> Industrial plastic blender machine plastic gravimetric doser blender mixing machine For injection machines

>> Mingde 150L Plastic Granulator Machine

>> 300 X1800mm Graphite Electrode with Nipples for Eaf for Welding Cast Steel

>> 280kg Electric Hexin Wooden Case Cloth Automatic Laminating Cutting Machine

>> Single-Side Double-Side Hot/ Cold Peel 60cm 30cm 33cm 43cm Dtf Transfer Pet Film for Digital T-Shirt Printing Machine Dtf Printer

>> 54inch Butterfly Cone Fan for Poultry

>> Plastic Caps Processing Machine / Injection Machinery Price

>> Beauty Skin Body Care Spray Fashion Deodorant Body Spray

>> Precision Vertical Knee-Type Milling Machine for Metal Fabrication

>> Weichai Yto Engine 180HP Tractor

>> Pharmaceutical Grade Ultrafine Material Impact Mill Pin Mill Particle Size D50: 10-45um

>> custom printing aluminum foil instant slimming coffee packaging bag

>> No noise no asbestos D1841/GDB7915 disc brake pads manufacturers with 20 years experience

>> Automatic Advanced Industrial Wood Sawdust Chicken Duck Bird Animal Feed Soybean Meal Pellet Cooler with Vibration Screen and Fan

>> White Granulated Sugar Production Line 1t/H Impact Pin Mill

>> Digital outer battery box home hotel bank code money parcel package safety cash safe drop off box with a drop gate

>> Woodworking 3800mm High Precision Full Automatic Horizontal MDF Plywood Boards Cutting CNC Computer Beam Saw Machine

>> Professional Commercial Vegetable Meat Mixer Sausage Burger Patty Mix Filling

>> Cool Hot Water Circulating in Line Booster Pumps Single-Stage

>> Aluminum China Door Waterproof Bathroom Door 3D Model Design Graphic Design Modern Commercial Rolling 3 Years Free Spare Parts

>> New Style Aluminium Doors Design for Mauritius

>> Cbmmart Cost-Effective Modern Lacquer Finish MDF Board Plywood for Kitchen Cabinet

>> High Quality Liquid Silicone Rubber Injection Moulding Machine with Factory Price

>> Auto accessories for BMW X6 F16 change luma style wide body kits 2014 up

>> PVC PPR UPVC Pipe Fitting Plastic Injection Molding Machine