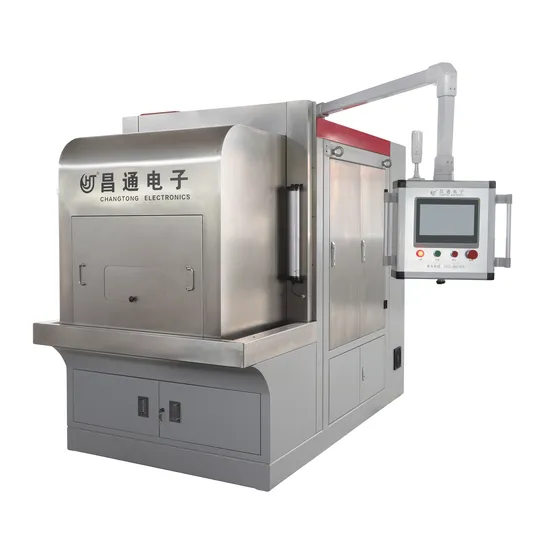

Advanced Magneticblock Cutting Machine for Precision Solar Applications

| US$47,000.00-200,000.00 | 1 set (MOQ) |

Basic Info.

Model NO.

CHTXQ-690F

Type

CNC Cutting Machine

Usage

Ceramics, Glass, Jadestone, Granite, Marble

Application

Art & Craft, Construction, Mineral Industry, Stone Industry

Source Voltage

380V

Automation

Automatic

Cutting Ability

High Speed

Control

CNC

Certification

CCC, ISO, CE

Transport Package

Package

Specification

1830*2800*2650

Trademark

ChangTong

Origin

China

HS Code

84649010

Production Capacity

100000set

Product Description

Equipment use: This state-of-the-art model is engineered to optimize cutting efficiency for our valued customers. With an impressive roller length of 690mm and a versatile table size of 170/145mm*690mm*160mm*2 version, it is expertly designed to facilitate precision cutting for products with thicknesses ranging from 0.3mm to 65mm.CHTXQ-690F Double Plate Multi-Wire Cutting Machine - Unveiling its Remarkable Features

1. Experience the innovation of four motors independently driving each roller. This advanced design ensures that each roller serves as a drive shaft, significantly reducing the wear on the steel line and enhancing roller longevity. The roller bracket's mounting hole is expertly molded using a processing center, ensuring perfect spindle installation with coaxial alignment.

2. The equipment is optionally equipped with a state-of-the-art LED display, providing cutting data in a clear and intuitive manner for enhanced operational insight.

3. Designed with user convenience in mind, the machine allows material to be cut from the bottom up, streamlining the loading and unloading processes.

4. Offering two distinct models, this machine comes in both high-speed and standard versions. The high-speed variant delivers superior performance with elevated line speeds and cutting efficiency, allowing for the use of thinner diamond lines when cutting identical materials.

5. With the inclusion of transverse movement capabilities, the table can be moved back and forth seamlessly, enabling tile cutting and versatile single-line cutting functionality.

6. The expansive loading area, measuring 170/145mm*690mm*160mm*2 version, significantly boosts cutting efficiency, accommodating larger volumes of material.

7. Exceptional spindle accuracy of ≤0.01mm is achieved through the patented structure dust technology (Patent No. ZL201320681902.7), ensuring stable operation and easy disassembly, making maintenance a breeze.

8. Engineered for simplicity and ease of use, this machine boasts an automatic lifting shield and a fully expandable workbench, facilitating effortless material and roller loading and unloading.

| unit | parameter | |

| Maximum Worksize | mm | 170/145*690*160*2 |

| cutting thickness | mm | 0.6~65 |

| running speed | m/min | 0~2200 |

| Table lift stroke | mm | 220 |

| Table cutting feed speed | mm/hour | 0.1~100 |

| The amount of wire output from the supply wheel | Km | 30(φ0.2diamond wire) |

| Diamond diameter | mm | φ0.06~φ0.35axle |

| Roller outside diameter*number of axles | mm | φ155/φ180*690*4 |

| boundary dimension | mm | ≈1830*2800*2650 |

| machine weight | Kg | 6500~115000 |

| power | AC380V/50HZ three-phase four-wire | |

| Total machine power rating | Kw | 54 above |

This innovative machine is a double-station multi-wire cutting marvel, designed for precision diamond wire processing. Capable of simultaneously processing two plate materials, it features a roller length of 690mm and a maximum cutting area of 220mm*690mm*160mm*2 version. With its rotary tool holder function, it handles cutting blade thicknesses from 0.5mm to 65mm, offering both single-line and multi-line cutting capabilities. It excels in processing hard and brittle materials in batch straight sheet form.

This model stands as a multi-line cutting machine, tailored for diamond line processing. Featuring a roller length of 570mm and a maximum cutting area of 220mm*570mm*160mm, it incorporates a rotary tool holder function perfect for slicing products with thicknesses between 0.3mm and 65mm. Ideal for batch processing of hard and brittle materials into straight sheets.

This compact model is a multi-line cutting machine, expertly crafted for diamond line processing. Available in single and double station variants, it's perfect for small batch product straight sheet processing. Its user-friendly design ensures hassle-free specification changes, handling cutting sheet thicknesses from 0.5mm to 30mm, and offering both single-line and multi-line functions. Particularly suited for small batch processing of hard and brittle materials.

Founded in 1998, Yutian Changtong Electronics Co., Ltd. has evolved from its origins as Yutian Changtong Electronics Factory. In 2007, it underwent a strategic restructuring to its current form and was honored as a high-tech enterprise in Hebei Province in 2001 and later as a national high-tech enterprise in 2016. The company expanded its reach with a branch in Yantai, Shandong Province in 2006. As a national high-tech enterprise, it seamlessly integrates research and development, production, sales, and service, continually pushing the boundaries of innovation.

Product Introduction

Main Products: Yutian Changtong Eiectron Co., Ltd. specializes in a diverse range of products including quartz crystal chips (frequency sheets), green silicon carbide powder, multi-line cutting machines, and electronic mechanical equipment, each designed to meet the highest standards of excellence.

Quality Certification

In the spirit of pioneering innovation and with the guiding principle that science and technology are the foremost productive forces, Yutian Changtong Eiectron Co., Ltd. has forged strategic alliances with renowned academic institutions and research bodies to spearhead the development of cutting-edge products. We are proud to have collaborated with prestigious entities such as Northeastern University, Yantai University, Hebei University, Dongguan University of Technology, Beijing Institute of Printing Machinery, and the Chinese Academy of Sciences (units 203, 45, 707, and 607), culminating in numerous patented innovations. Among these, one distinguished patent is proudly featured in the National Science and Technology Database, underscoring our commitment to excellence.

Yutian Changtong Eiectron Co., Ltd. has been honored with numerous prestigious accolades that underscore our commitment to excellence and innovation. These include the distinguished titles of "High-tech Enterprise of Hebei Province," "Small and Medium-sized Enterprises of Science and Technology in Hebei Province," and the national recognition as a "National High-tech Enterprise." We also hold the esteemed designations of "Specialized and Special New Enterprise," "Municipal Enterprise Technology Center," "Municipal Industrial Design Center," and "National 3A Credit Enterprise." These accolades reflect our unwavering dedication to technological advancement and superior business practices.

Value Concept

Our core values are encapsulated in our commitment to "Ethical, Integrity Management." Yutian Changtong Eiectron Co., Ltd. has been consistently recognized by provincial, city, and county authorities as an A-level tax unit, an honest enterprise, and a quality and credit enterprise. Furthermore, we are celebrated as outstanding builders of socialist undertakings with Chinese characteristics, embodying the highest standards of ethical business practices and integrity.

>> UICE 4-pieces Green Nylon Blade Professional Quality Paddle Board Paddle Aluminum Paddle

>> Car Accessories Exterior Decorative for Infiniti QX50 Power Electric Tailgate Lift Rear Trunk Struts

>> EPS Foam Making Machine with CE

>> Microwave Vacuum Wood Dryer Kiln Machine for Timber Drying Saga

>> Round Edge Sanding Grinding Disc Grinder Wheel Vacuum Brazed for Marble/Granite/Quartz/Tile

>> Frozen Strawberry with High Quality

>> Feed Processing Pellet Maker Machines Chicken Feed Pellet Making Machine Pellet Machine

>> Hot Sale Walkie Type Stacker Electric Forklift Reach Walk Behind

>> good price ultrasonic plastic welding machine 20khz equipment plastic welder for sale

>> High Quality Cheap Price Outdoor Solar Powered Garden Lamp 100 LED

>> Metal Roof Tile Panel Cold Roll Forming Machine with High Speed

>> 2400mm Tissue Paper Making Solution for Capacity 8 Tons/Day

>> Wall Mounted Automatic Door System ID Card Reader Access Control Keypad

>> Xgj850p High Safety Factor Wood Pellet Machine with CE and Good Reputation

>> Graphite Electrodes

>> Hot Sale Dumbbells Hand Weight Set Barbell Exercise Fitness Dumb Bell Free Weight Dumbbell

>> Auto Egg Nest Individual 16 Holes

>> Disc Cutting Sawing Machine Hydraulic Power CNC Cutting Circular Saw Machine

>> Wheat Paddy Sorghum Combine Harvester Cag-2000b

>> 100% Cotton Pillow with Gusset Wall

>> Fujixun Wooden Gearless Sightseeing Passenger Goods Freight Residential Observation Capsule Home Villa Residential Panoramic Glass Elevator Lift

>> Tianlai Bm-8 8 Inch 120W Entertainment Speakers Wall Mounted Professional Audio Conference Speaker

>> Factory Price High Efficiency Mono Solar Panel 580W 550W 450W 700W Wholesaler

>> Diellea Men's mechanical automatic jade gold watch genuine business luxury Sapphire watch Waterproof 6032

>> Fish Hunter DL3C Fishing Lures 85MM/10G Hard Bait Lure isca artificial Realis pencil fishing baits

>> Hot Sales Horizontal Machining Center HMC500 CNC Milling Machine

>> Microfiber Dry Hair Cap Towel Wrap Quick Dry Hair Coral Velvet Embroidered

>> Combine Harvester Rubber Track 450*90*60 for Agricultural Machinery

>> Dynamic 180kw 6190 Gas Engine Generator Set

>> Fixtec 5L Pressure Sprayer 1.6bar Pressurized Lawn & Garden Water Spray Bottle with for Spraying Plants, Garden Watering and Household Cleaning