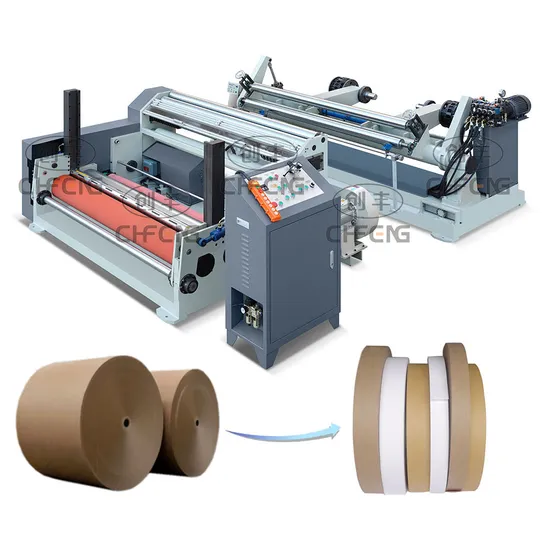

Cffq-200 Jumbo Paper Roll Slitter Rewinder Machine Paper Slitting Machine Paper Roll Cutting Machine

| US$10,000.00 | 1 sets (MOQ) |

Basic Info.

Model NO.

CFFQ-200

Material

Paper

Condition

New

Paper Type

Craft Paper

Warranty

12 Months

Size

3.3*1.2*1.2m & 3*1.7*1.1m

Custom Order

Accept

Weight

3200kgs

Industrial Use

Gift & Craft

Power(W)

15kw

Surface Handling

Painting

Voltage

380V / 3phase / 50Hz

Printing Handling

Other

Brands of Components

Can Be Customized

Transport Package

Seaworthy Package (Wooden Case / Pallet)

Trademark

Chuangfeng

Origin

Zhejiang, China

Production Capacity

10 Set/Sets Per Month

Product Description

Product DescriptionUsage: CFFQ-200 Jumbo Paper Slitting Rewinding Machine is suitable for Kraft paper; Tea paperboard; Bobbin paper; Art paper etc.

Features:

1. Double blades (upper blades and down blades) slitting. Cutting edges are more smooth and neat.

2. Adopt shaftless material loading device which can bear 2000kgs weight.

3. Pneumatic loading and unloading system; material paper roll loading and finished rolls unloading to be automatically.

Technical Parameter

CFFQ-200 Split Paper Slitter Rewinder

| Main Parameters | Control System | ||

| Material paper | 60-600gsm | Main motor | 15kw Wannan |

| Unwind width | 600-1600mm | Electric components | CHNT |

| Unwind diameter | 1400mm | Pneumatic components | Jingwei |

| Rewind diameter | 1400mm | Bearing | Haerbin |

| Minimum slitting width | 35mm | Main Configuration | |

| Working speed | 0-200m/min | Jumbo paper loading device | 1 pair (76mmID) |

| Speed regulation | by Inverter | Hydraulic lifting device | 1 set |

| Material paper loading device | Shaftless | Discharging air cylinder | 1 piece |

| Loading | Automatically by Hydraulic | Braking device | 2 pieces (air brake) |

| Unloading | Automatically by pneumatic | Blades | 20 sets (top&bottom) |

| Rewinding device | Air expanding shaft | Operating box | 1 set |

| Power supply | 380V 50Hz 3Phase | Tool | 1 set |

| Measurement & Weight | Curved roller | Have | |

| Measurement | L3300*W1200*H1200mm (unwind side) | | |

| L3000*W1700*H1100mm (rewind side) | | | |

| Weight | 3000kgs | | |

Pictures

-- Slitting& Rewinding Side.

a. Multi Blades Slitting -- minimum slitting length is 35mm.

b.Rewinding part adopted with air inflatable shaft; finished rolls can be removed more easier.

-- Shaftless Unloading System; Pneumatic Lifting (hydraulic lifting system can be customized)

-- Rewinding side has curved roller and finished rolls can be seperated automatically

company 0801

>> Durable Powder Coated Aluminum Gazebo Opening Louvered Roof For Pergola Cover

>> Atc CNC Router A4-2030-L8 Woodworking Router with 2000*3000mm Automatically Tools Change Working on Wood/MDF/Acrylics

>> bending sheet metal fabrication decorative custom perforated sheet metal

>> Pet Products Wholesale Cat Litter Natural and Eco-Friendly 6L Tofu Cat Litter Clumping Cat Sand Fabricado En China Eco Cat Litter

>> Ek25 Household Multifunction 5kg 3kg Electronic Smart Weighing Digital Kitchen Food Weight Scales

>> CE Approved DIN Surely Standard Packaging or Customized Stainless Steel Aluminum Die Casting

>> Diesel Electric Bakery Convection Furnace for Meat, Bread, Cake, Biscuits

>> Wholesale Professional High Light Straight Cold Fusion Double Drawn I Tip Human Hair Extensions

>> Outdoor bicycle Waterproof Hydration Backpack for 2L Hydration Bladder

>> Clamp Car Customized Aluminum Cnc Sheet Metal Stamping Parts

>> Affordable Laser Panel Cutting Machine for Flexible and Rigid Boards

>> M5SV Fresadora Taiwan Spindle Vertical Turret Milling Cutting Lathe Grinding machine made in China

>> Plastic Wastewater Continuous Decanter Centrifuge 3phase Horizontal Decanter

>> 2600w Plastic Cup Roll Film Weldling Machine Plastic Vaccum Sealing Milk Tea Cup Sealing Machine

>> Sheet Die Cutting Machine for Food Box Making

>> Unique Customized Oil Painting by Oiuytoh - Originating From Yiwu City

>> Vmc850 12000rpm Fanuc CNC Milling Machine Controller Vertical (Horizontal) Machining

>> High Gloss Piano Finish Wooden Pen Storage Packing Display Gift Box

>> New decorative iron grill window doors designs iron gate front doors

>> Forest Kids Cartoon PE Assorted Adhesive Bandage Strips

>> Potato Harvester

>> 2D Barcode Scanner Long Range Qr Code Scanner Reader Inventory Wireless Barcode Scanner

>> D Cut Non-Woven Fabric Bag Making Machine Ultrasonic Non Woven Bag Making Machine Price

>> API Industrial Small Diameter Wedge Gate Valve, Dedicated to Petroleum

>> 2-PC 4-PC 5-Claw Snap Button Attaching Machine Automatic

>> SGDS-08A15A Servopack Modular 750W Power Industrial Spare Parts

>> Fabric Machine Pleating High Cost Performance

>> 16oz 13.5" Hollow Fiberglass Handle Claw Hammer Hand-Tools Hammer

>> China Manufacturer High Durable Automatic Hot Sale Tapping Machine

>> Air/ Sea Freight Express Delivery Agent UPS, FedEx, DHL International Express From China to Worldwide