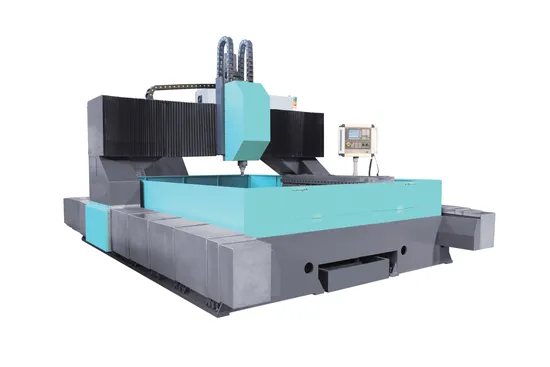

Heavy-Duty CNC Drilling Machine for Precision Steel Plate Processing with Advanced Drilling Equipment Efficient Steel Plate Fabrication of Steel Plate

| Negotiable | 1 Piece (MOQ) |

Basic Info.

Model NO.

PHD2020

Structure

Vertical Drilling Machine

Layout

Vertical

Controlling Mode

CNC

Number of Shaft

3

Automatic Grade

Automatic

Precision

High Precision

Certification

CE, ISO 9001

Condition

New

Processing Size

2000X2000mm

Processing Thickness

15-100mm

Model of Spindle

Bt50

Feeding Stroke

260mm Servo Feeding

Tapping Diameter

M20mm

Power of Spindle Motor

7.5kw

Control Mode

Knd CNC System or Siemens System

Dimension

4200X2850X2750mm

Weight

7200kg

Transport Package

Plastic Film as Standard Package

Specification

PHD2020

Trademark

FARIN

Origin

China

Production Capacity

50

Product Description

ubeCNC Plate Drilling and Milling Machine for Steel plate and tubesheet PHD Seriesheet PHD Series

The machine is mainly used for drilling and milling of steel structure, iron tower, bridge, mechanical processing and other industries, such as connecting plate and floor board, drilling and milling of tubes, baffles and flanges in industries such as boiler, petrochemical, pressure vessel and so on; drilling holes, blind holes, step holes, chamfering and light milling.

This machine is mainly composed of bed,gantry,drilling and milling power head,electric control system,centralized lubrication system,cooling system and chips removal system etc.

1.The bed is made of high quality gray cast iron, no need foundation.

2.Double side lead screw synchronous driving system, stable performance, flexible movement, accurate positioning.

3.Adopting slide head drilling and milling power head, it can realize the automatic conversion of fast forward, drillng and quickly, and has the function of automatic chip breaking.

4.Adopt BT50 high speed internal cooling precision spindle, can adopt hard alloy internal cold drill bit, processing efficiency is high.

5.Equipped with pneumatic knife cylinder automatic knife replacement, optional tool magazine.

6. KND CNC system+ servo motor control, can directly transfer Auto CAD drawings to general processing program.

7.Automatic chip removal, cooling liquid recycling.

Technical parameters:

| Model | PHD1616 | PHD2016 | PHD2020 | |

| Processing size | LxW(mm) | 1600x1600 | 2000x1600 | 2000x2000 |

| Thickness(mm) | 15-100 | |||

| Drilling spindle | Quan. of spindle | 1 | ||

| Model of spindle | BT50 | |||

| Speed of spindle(r/min) | 30-4500 | |||

| Feeding stroke(mm) | 260(Servo feeding) | |||

| Tapping diameter(mm) | M20 | |||

| Clamping mode | Manual | |||

| Power of motor | Spindle motor(KW) | 7.5 /11(Servo motor) | ||

| X-axis(KW) | 2×2.3 | |||

| Y- axis(KW) | 2.3 | |||

| Z- axis(KW) | 2.3 (with brake) | |||

| Precision of positioning(mm) | 0.1 | |||

| Precision of repeating positioning(mm) | 0.08 | |||

| Control mode | KND CNC system, model: KND1000 | |||

| Weight of machine(T) | 5.5 | 6.6 | 7.2 | |

| Dimension(m) | 3800x2050x2750 | 4200x2450x2750 | 4200x2850x2750 | |

| Optional- Tool magazine | 6units of Straight tools | |||

| Optional- automatic clamp | 12 units of hydraulic clamper | |||

Packaging & Shipping

Company Profile

>> High Performance 90 Degree 180 Degree 360 Degree Floor Mounted Articulating Arm Folding Jib Crane Fixed Jib Crane with High Quality and Best Price for Factory

>> Perfect Price Wood Laminate Floor Oak Color Customized

>> Adjustable Hinged Knee Support Brace for Active Lifestyles Pain Relief Injury Recovery

>> Farm Tractor Sweet Mini Single-Row Potato Harvester for Sale

>> 25cc Gasoline Chainsaw Petrol Outdoor Used 12 Inch Guide Bar Chain Saw

>> Pole Solar Ceiling Fan Small Surface Plastic Mounted Weatherproof Terminal Box

>> Industrial Dehumidifier Dwxd102 Refrigerant Gas Compressor

>> Construction Equipment Small/Mini Excavators/Diggers Xe135b with Bb-4bg1trp Engine

>> Erythrocyte Aggregation Rehabilitation Therapeutic And Fatigue Recovery Therapeutic Medical Device

>> Glass Bottle Beer Tunnel Pasteurizer

>> Automotive parts front hood gas spring gas strut for Toyota Hilux Vigo 2005-2014

>> Standard Brake Pad 425464 for Peugeot Brake Pad

>> YFMC-720A Manual Roll to Roll Lamination Machine

>> Automatic CNC Milling Machine Vmc7032 for Metal Processing

>> Jinko/Ja/Trina/Longi/My Solar Panel Best Wholesale Mono 550W560W 565W570W 575W 580W 585W 590W PV Photovoltaic Half Cells Panels Price Energy Tx-Solares Paneles

>> Yt5l-BS Lead Acid Battery AGM Separator Envelopes

>> Multifunction Automatic Walking Tractor Reaper Mini Rice Wheat Harvester New Small Combine Harvester Price

>> Outdoor Attractive Chinese New Year Candy Lantern Festival Decoration

>> Auto Electronic Control System F18 Angle Eyes Module for BMW 5 Series F18 6312 7262 731

>> Hot sell meat cutting saw bone machine price on sale

>> WMTCNC vertical machining center VMC855L cnc machine centers

>> Plastic Recycling Plant Waste PP PE Film and Bags Hot Washing Machine

>> 600 Tons Plywood Hot Press Machinery/ Hot Press Machine

>> Qizhi Easy Operate Internal Installed Pneumatic Flange End Facing Machines

>> ZDS lead-edge Automatic Feeding Machine

>> SKMEI high quality black blue paper watch box carton boxes with customized logo

>> Modern straight stairs staircase design indoor steel structure floating staircase luxury indoor metal stairs

>> OIML Standard Cast Iron Test Weight 5kg 10kg 20kg Standard Weights Calibrated Weight

>> China Preserved Bunny Tail Flower for Chistmas Decoration Flower Gifts

>> Manufacturer Customization Sock Toe Sewing Machine for Christmas Socks