Versatile 30000L Magnetic Agitator Chemical Reactor for Industry Applications

| US$247,000.00-268,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

FCHA

Type

Reaction Kettle

Material

S30408, Q345r,S32168

Capacity

34.5m³

Structure

Internal Coil, External Half Tube

Pressure

Positive

Heating

Steam, 7ºC Water

Heat Transfer Structure

External Half Tube, Inner Coil Tube

Automatic Grade

Automatic

Condition

New

Rotation Speed

230r/Min

Power

110kw

Seal Type

Magnetic Seal Zero Leakage

Total Weight

47618

Lead Time

100 Days

Oversea Branch

California, USA

ODM

Available

OEM

Available

Specification

34.5m³

Trademark

LUHAO

Origin

China

HS Code

84198990

Product Description

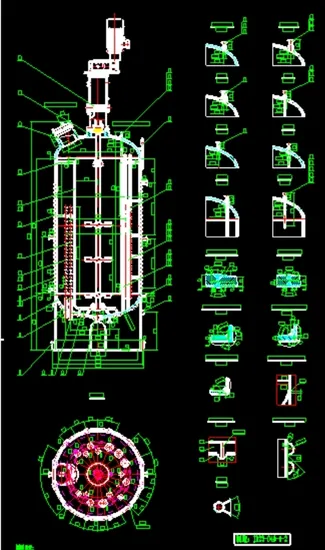

Vessel Capacity m³: 34.5 Material: S30408+Q345R Design pressure MPa: 7.0 Design temperature ºC: 100 Work pressure MPa: 6.0 Work temperature ºC: 80 Working life: 10 years External half tube Capacity m³: 1.9 Material: 20/Q345R Design pressure MPa: 0.6 Design temperature ºC: 165 Work pressure MPa: 0.5 Work temperature ºC: 150 Medium: Steam Heat exchange area m2: 85.5 Coil tube Capacity m³: 0.60 Material: S32168 Design pressure MPa: 0.6 Design temperature ºC: 30 Work pressure MPa: 0.5 Work temperature ºC: 7 Medium: 7ºC water Heat exchange area m2: 60.6 Total weight Kg: 47618| *For confidential reason, the drawing is in low definition. Please contact us for more information. |

https://luhaochemreactors.en.made-in-china.com/product-list-1.html

| LUHAO Chemical Machinery Co. Ltd | ||||||||||||||

| Pressure Vessel Design Information Collection Table | ||||||||||||||

| Vessel | Jacket (Coil) | |||||||||||||

| Work Medium | Name | |||||||||||||

| Components | ||||||||||||||

| Density (Kg/m³) | ||||||||||||||

| Characteristics | ||||||||||||||

| Viscosity (cP) | ||||||||||||||

| Flow Velocity(m³/h) | ||||||||||||||

| Design pressure (Mpa) | ||||||||||||||

| Work pressure (Mpa) | ||||||||||||||

| Design temperature(ºC) | ||||||||||||||

| Work temperature (ºC) | ||||||||||||||

| Wall temperature (ºC) | ||||||||||||||

| Diamter (mm) | ||||||||||||||

| Length (mm) | ||||||||||||||

| Capacity(m³) | ||||||||||||||

| Effective capacity (m³) | ||||||||||||||

| Corrosion allowance (mm) | ||||||||||||||

| Corrosion speed (mm/year) | ||||||||||||||

| Recommended Materials | ||||||||||||||

| Lowest value of average monthly temperature(ºC) | ||||||||||||||

| Site location | ||||||||||||||

| Installation condition | Indoor Outdoor | |||||||||||||

| Catalyst Volume(m³) | ||||||||||||||

| Catalyst Density(Kg/m³) | ||||||||||||||

| Heat Transfer Area() | ||||||||||||||

| Coil Specification | ||||||||||||||

| Basic Wind Pressure(Mpa) | ||||||||||||||

| Seismic Basic Intensity | ||||||||||||||

| Ambient Temperature(ºC) | ||||||||||||||

| Site Type | ||||||||||||||

| Operating Mode | ||||||||||||||

| Insulation Materials | Name | |||||||||||||

| Thickness | ||||||||||||||

| Density (Kg/m³) | ||||||||||||||

| Seal Requirements | ||||||||||||||

| Liquid Level Gauge | ||||||||||||||

| Emergency Cut-off | ||||||||||||||

| Static Electricity Removal | ||||||||||||||

| Anti Eddy Current Requirement for Liquid Outlet | ||||||||||||||

| Installation and Mantainance Requirements | ||||||||||||||

| Expected Useful Life (years) | ||||||||||||||

| Safety accessories | Vessel | Jacket (Coil) | ||||||||||||

| Location | ||||||||||||||

| Type | ||||||||||||||

| Specification | ||||||||||||||

| Quantity | ||||||||||||||

| Set pressure(Mpa) | ||||||||||||||

| Burst disc | ||||||||||||||

| Burst pressure(Mpa) | ||||||||||||||

| Safety discharge(kg/h) | ||||||||||||||

| Agitator | Type | |||||||||||||

| Impeller Diameter(mm) | ||||||||||||||

| Speed(r/min) | ||||||||||||||

| Motor | Model | |||||||||||||

| Power(kw) | ||||||||||||||

| Explosion Proof Grade | ||||||||||||||

| Speed reducer | ||||||||||||||

| Piping Table | ||||||||||||||

| No. | Dimension | Pressure | Connection Size Standard | Connection Surface Type | Function | |||||||||

| a | ||||||||||||||

| b | ||||||||||||||

| c | ||||||||||||||

| d | ||||||||||||||

| e | ||||||||||||||

| f | ||||||||||||||

| g | ||||||||||||||

| h | ||||||||||||||

| j | ||||||||||||||

| k | ||||||||||||||

| Other Requirements if any | ||||||||||||||

>> M18 NPN PNP Diffuse Reflection Infrared Photo Sensor Through Beam PNP Photoelectric Switch

>> High-Performance 220V Voltage Regulator for 2kw Foam Cutter

>> SIMCom SIM68MLB GNSS Module Integrated with GPS Beidou QZSS

>> Basketball Backpack Large Sports Equipment Bag with Shoes Compartment

>> Vmc600 Horizontal Machining Center Automatic Machining Center with Metal Material Shell

>> China Factory Supplied Top Quality Grade Statue

>> Stainless Steel Bottles Recycling Line

>> Green Color PVC Coated Chain Link Mesh (R-GHW) Galvanized Wire Mesh

>> mens black metal shaving razor brush stand with craft paper box grooming set

>> 45 Degree Rotary Table Horizontal Milling Machine (HUM32A)

>> Small Power LED Street Light Hot Sale Factory Price LED Outdoor Light with Smart LED Driver Motion Sensor Die-Casting Aluminum CE RoHS Garden Lighting

>> Components Tractor Top Link Rear Suspension Point Linkage Tractor Linkage

>> High Quality Tank Container Glassfiber Tank Winding Tank GRP FRP Fiberglass Products Filament China Tank Supplier

>> Jps-320fq-Tr Automatic Turret Rewinder Slitter/ Slitting Rewinding Machine for Self-Adhesive Thermal Paper Label Film Sticker Roll

>> IP66 Portable Multi Gas Detector 4 in 1 Smart Detector Combustible and Toxic Detector Lel/O2/Co/H2s

>> 36kV Post Composite Insulator ANSI standard

>> High Cutting Efficiency Diamond Wires for Cutting Granite/Diamond Rope Saw / Wire Rope Cutter

>> Dongyou Save Liquid Usage Amount PU Foaming Machine Dy-Hgc7403

>> 51.2V 200Ah LiFePO4 Battery

>> Plastic PE PP Recycling Machinery

>> Gantry Type Milling Machine X2020A Worktable 4000X2000

>> Good Price Pure Natural Dried Rice Bean Small Red Bean for Export

>> China Manufacturer Roll Stands Suitable for Various Patient Monitor

>> CNC Miling Machine Turning Slant Bed Turning and Milling CNC Lathe Machine Servo Motor Slant Bed CNC Turning Machine

>> Double Track Manual Tile Cutter Small-Sized Irregular 500mm 600mm Ceramic Tile Cutting Machine

>> 3 Point Hitch Plow for Tractors 3 Disc Plough Farm Implement 1LYQ-320

>> Heavy-Duty Truck Tire Crusher for Efficient Waste Tyre Shredding

>> 30000m3 Particle Particle Board Production Line

>> Durable UL Certified AC Power Cord for North America

>> Factory Price 3 Pin Ac Pc Power Supply Lead Cable For Computer And Laptop